Operation

Single screw pump

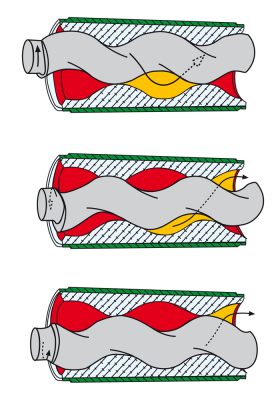

The CMO pumps function thanks to a tested mechanism composed of a chromium-plated or stainless steel worm screw and by a stator covered on the inside in plastic. Rotation of the worm inside the stator creates a series of hermetic gaps that are moved along the suction-delivery axis thereby creating the pumping action (see diagram at right).

This type of pump can be used for an infinite number of applications due its special construction, the materials used, the technical measures adopted and the singular working mechanism that guarantees maximum performance whether pumping must or milk, chocolate, synthetic resins, bitumen or foundry sludge.

The SINGLE SCREW series of pumps are:

Lobe pump

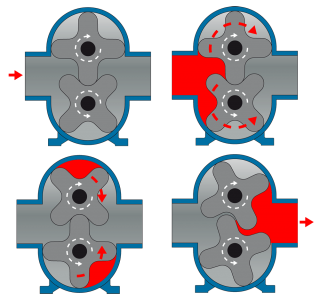

The heart of the machine is made up of two lobe rotors mounted on parallel axes. They rotate in a synchronized manner inversely to each other inside an airtight chamber. The rotors have three or four lobes depending on pump size. Combined rotor movement creates suction and delivery, and the special helical shape of the lobes guarantees more fluid movement without vibration (see diagram at right).

The two rotors can have different coatings depending on the type of material to be pumped. The pump’s airtight chamber is in grey cast iron, and it can be hard chrome-plated internally when used with particularly abrasive or aggressive fluids is foreseen. The mechanical seals are made of widia/widia.