HIGHLY ABRASIVE LIQUID SLIGHTLY ABRASIVE LIQUID

Author Archive

Technical data

| TYPE | FLOW RATE l/min | BAR | rpm/min | Motor |

|---|---|---|---|---|

| PI 40 140/20 | 40 | 20 | 200 | CC 100 |

| PI 55 200/26 | 75 | 26 | 200 | CC 160 |

| The flow rates indicated above regard the maximum rpm at 1 bar. | ||||

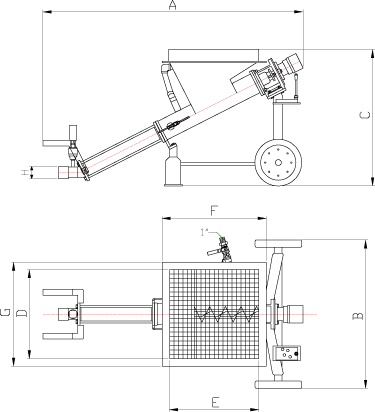

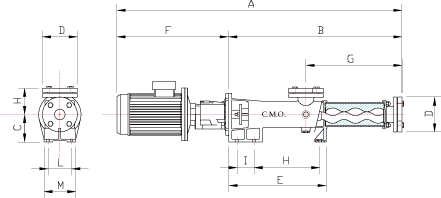

| TYPE | A | B | C | D | E | F | G | H |

|---|---|---|---|---|---|---|---|---|

| PI 40 140/20 | 1680 | 1000 | 920 | 600 | 600 | 700 | 700 | 1'' 1/2 |

| PI 55 200/26 | 1800 | 1000 | 920 | 600 | 600 | 700 | 700 | 2'' |

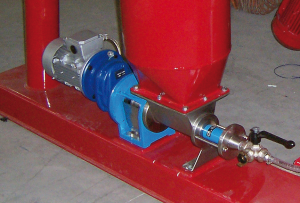

Gallery

Features

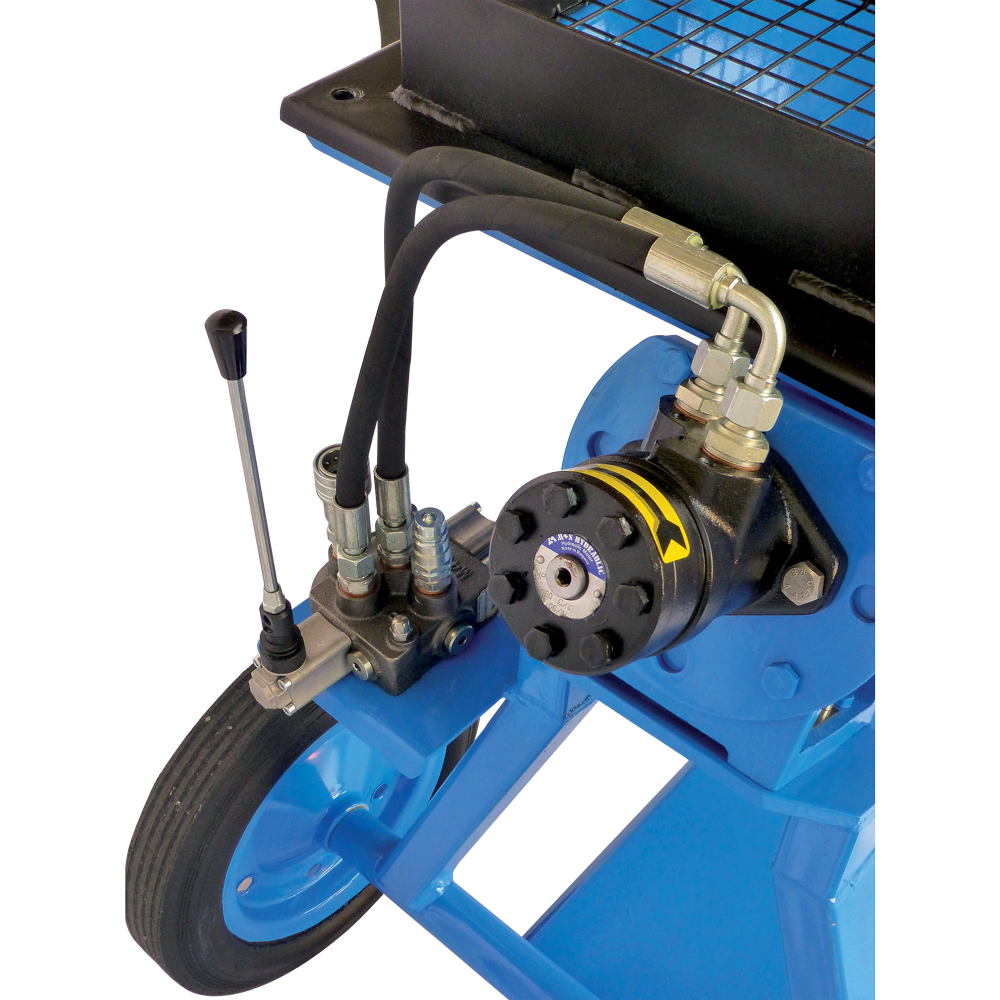

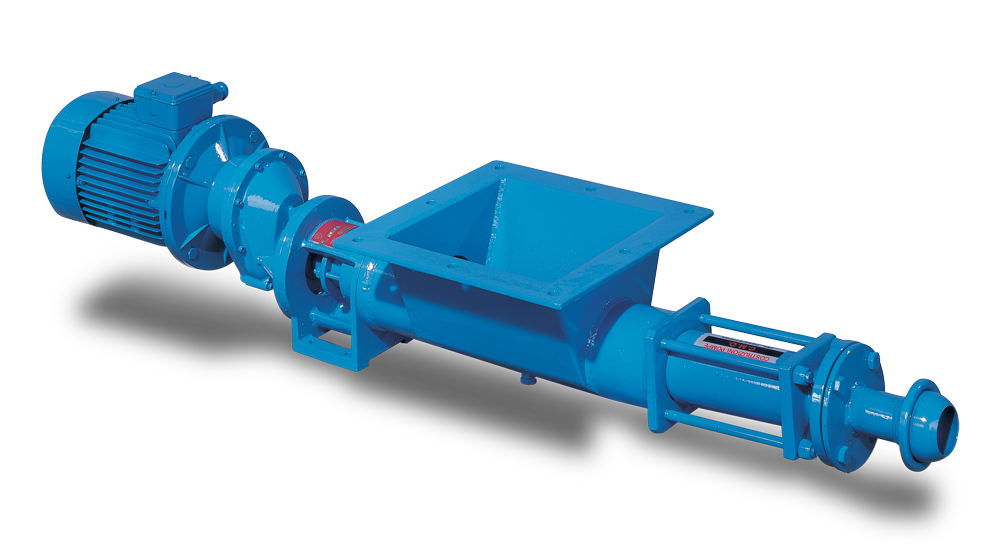

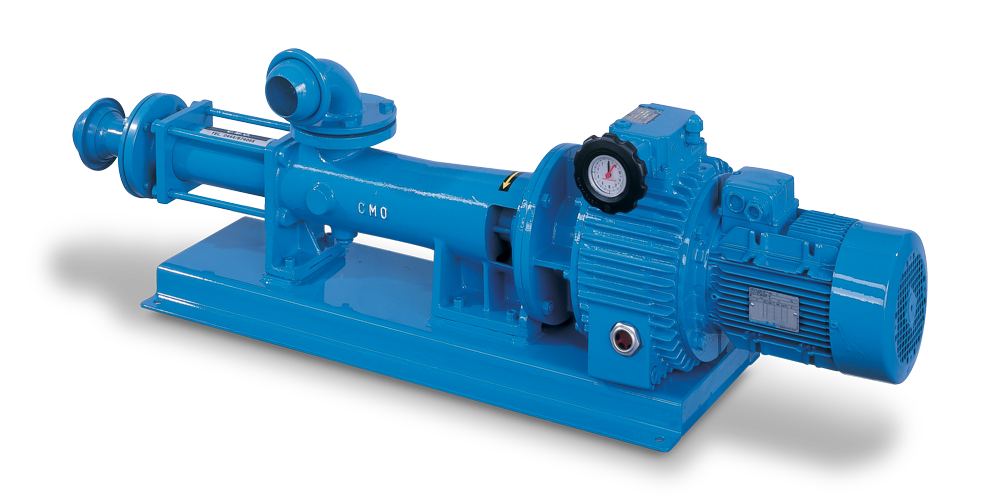

The C.M.O. PI series single screw pump was developed after years of working closely with the leading mixing machine manufacturers.

The C.M.O. PI series single screw pump was developed after years of working closely with the leading mixing machine manufacturers.

This machine permits the mixing of cement materials inside a special hopper with water and then to inject them directly at high pressures.

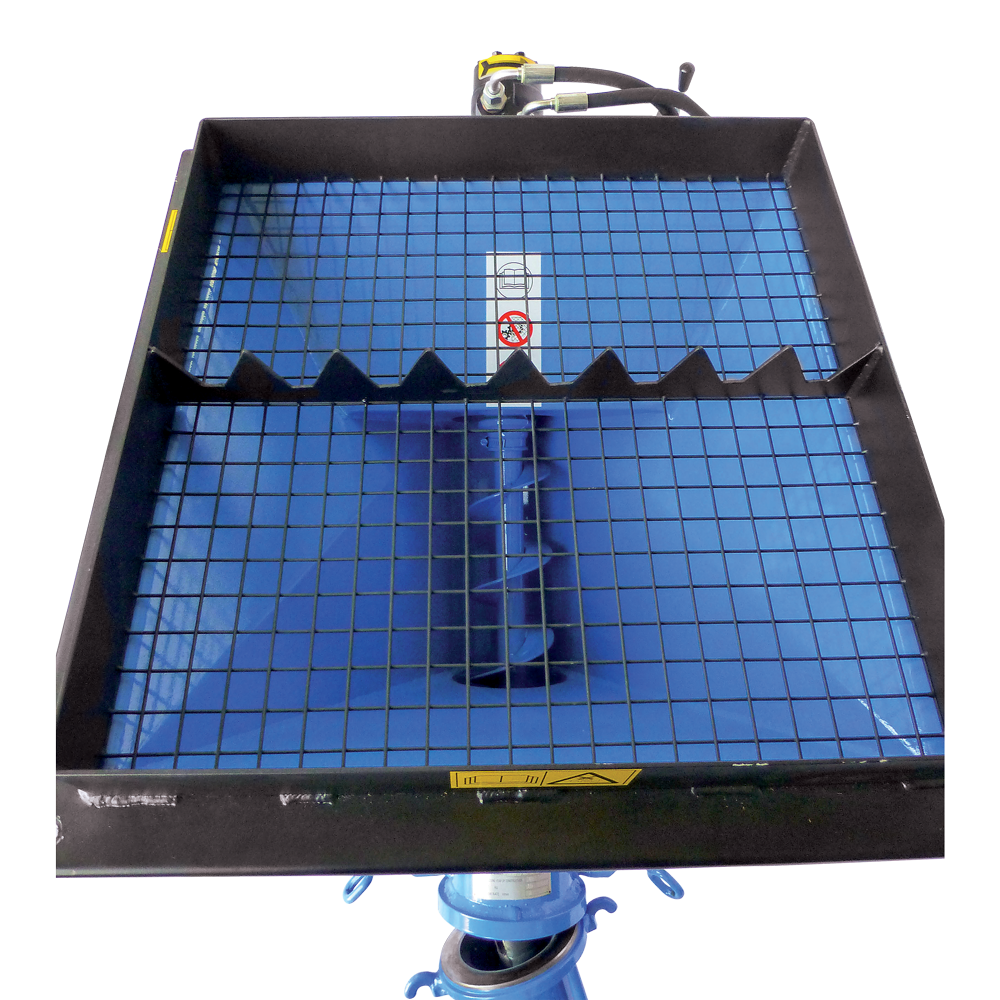

The light weight and the practicality of the trolley makes the pump particularly easy to manoeuvre even in the most restricted areas, whereas the capacious loading hopper, which is also provided with a sack breaker allows the machine to be directly installed beneath a silo.

The guillotine coupling between the joint with the feeding screw and the rotor ensures the simple disassembly and the replacement of the stator, thanks also to the lateral closing hinges that ensure rapid removal of the pumping compartment whenever necessary. Because it can be completely disassembled, the internal parts of the machine in contact with the product can be easily and thoroughly cleaned.

The standard machine can be equipped with a hydraulic motor controlled by a manual distributor that allows the inversion of oil flow for the inversion of pump rotation, or alternately with an electric gearmotor, which if mounted under inverter guarantees increased or decreased rotation speed and consequent variation in flow rate.

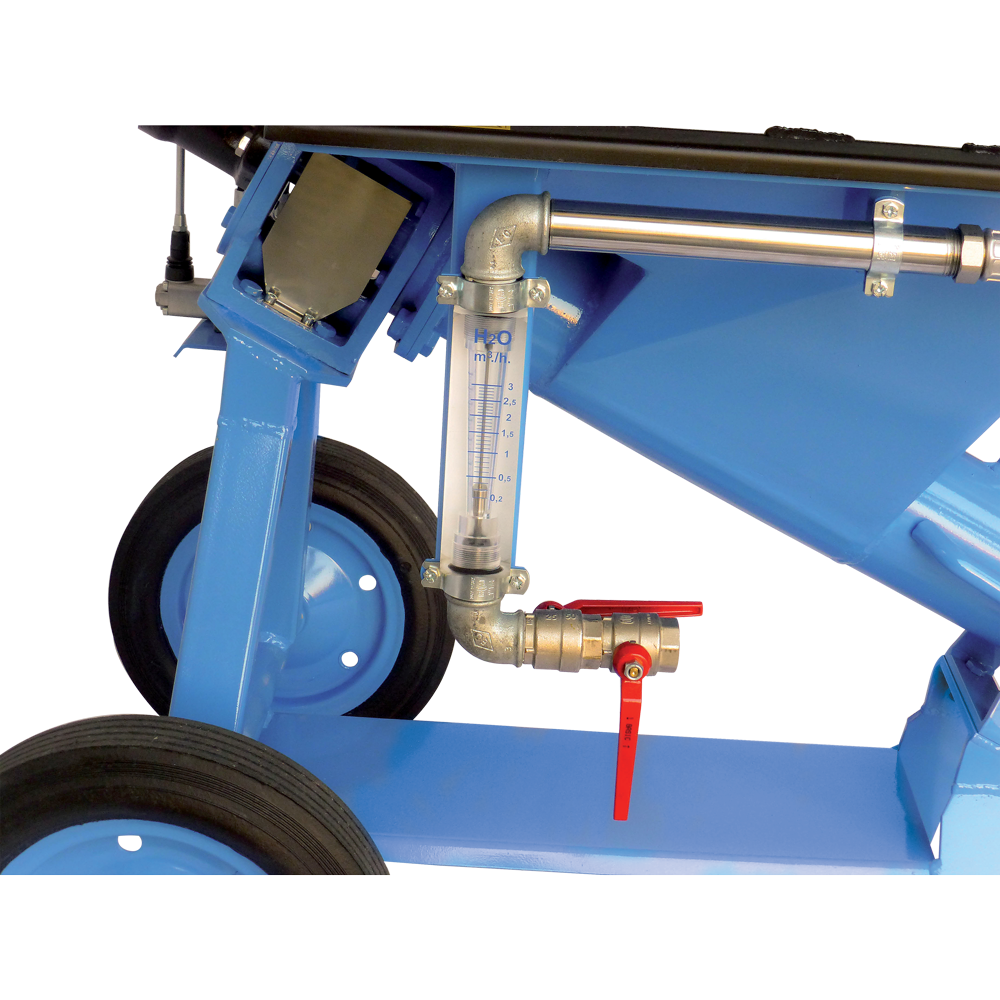

For better material mixing, the pump is equipped with metal mesh piping for water inlet and a flowmeter that guarantees a constant flow during the phases of mixing and injection.

The pump is also supplied with a diaphragm gauge installed at the pump outlet point that ensures a constant control of the outlet pressure during all work phases.

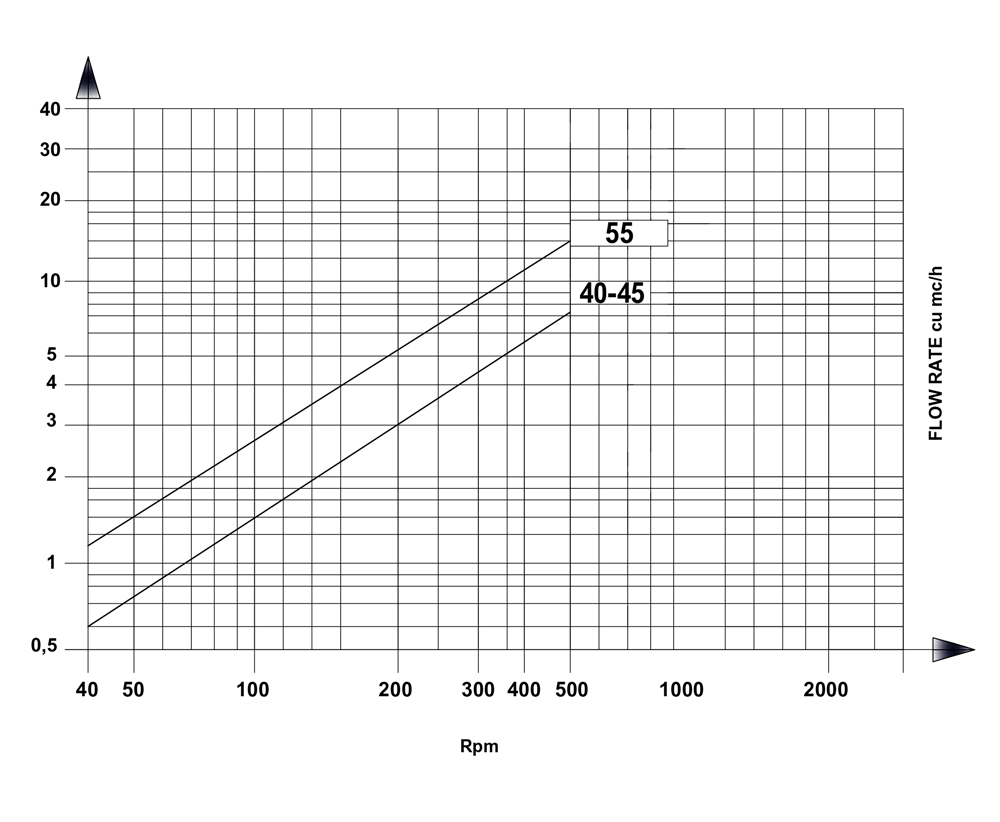

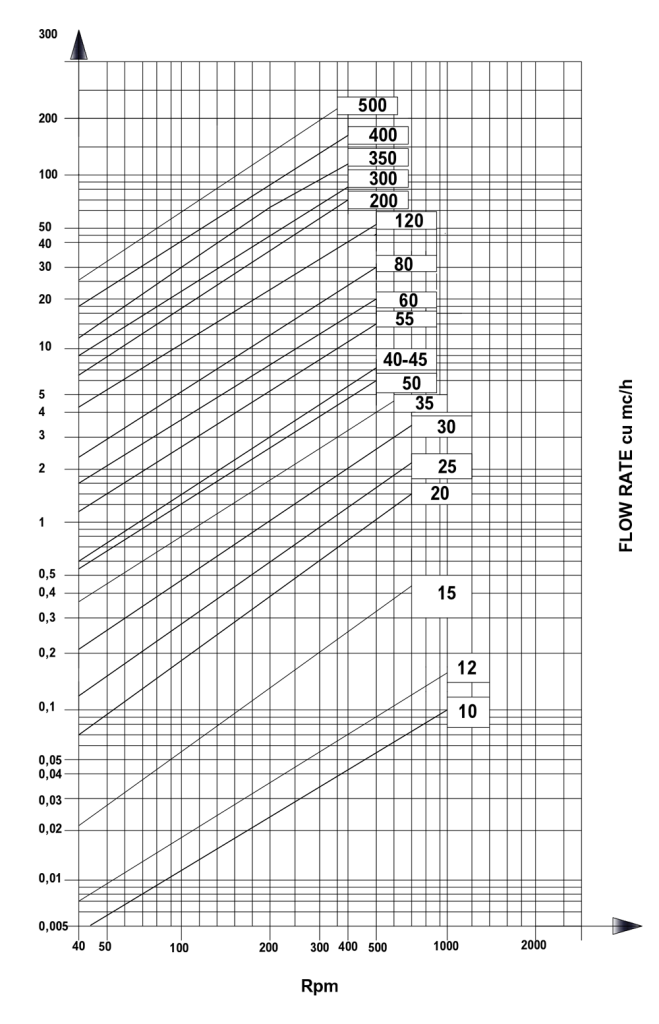

Flow Rate Curves

Standard geometry

HIGHLY ABRASIVE LIQUID SLIGHTLY ABRASIVE LIQUID

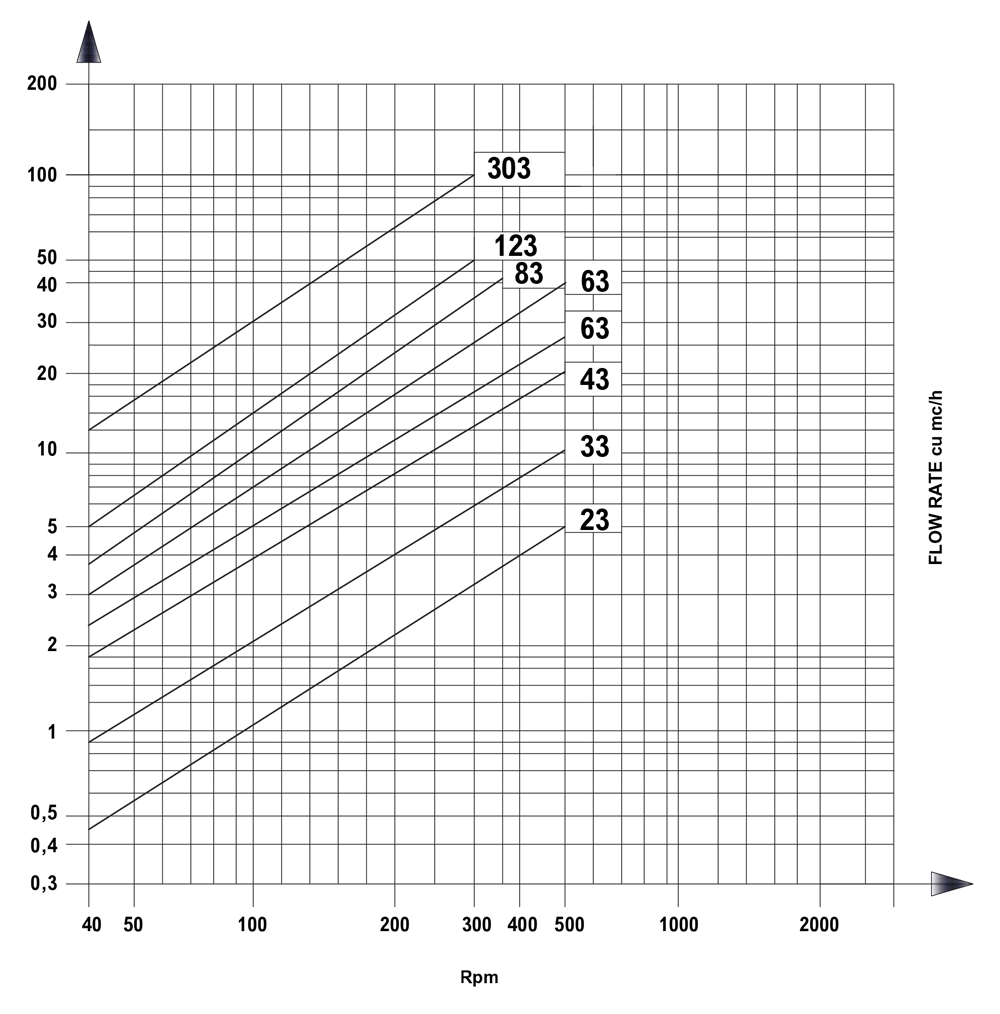

Twin screw geometry

HIGHLY ABRASIVE LIQUID SLIGHTLY ABRASIVE LIQUID

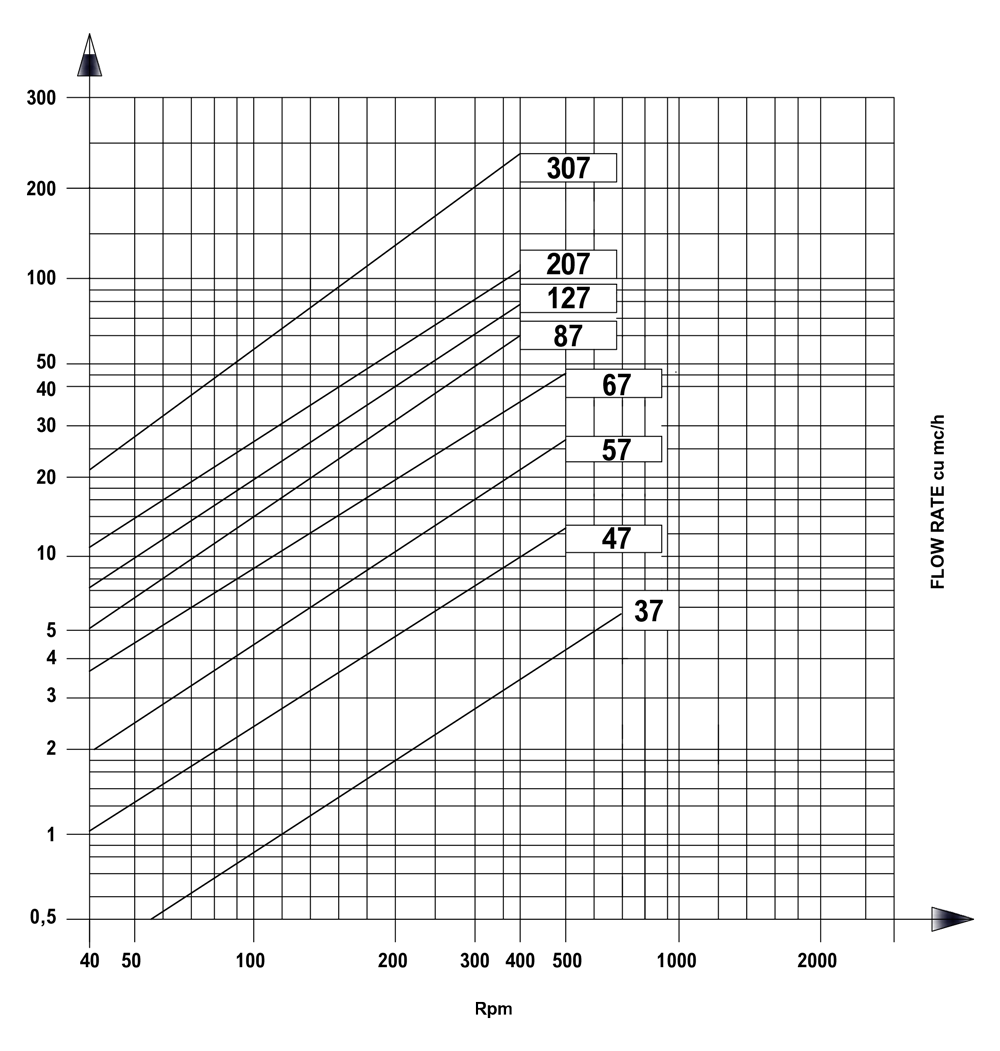

Long pitch geometry

HIGHLY ABRASIVE LIQUID SLIGHTLY ABRASIVE LIQUID

Technical data

| MN SERIES | |||

|---|---|---|---|

| TYPE | CAPACITY l/min. | HEAD bar | POWER HP |

| MN 10 3/5 | 3.3 | 5 | 0,75 |

| MN 15 10/7 | 10 | 7 | 1 |

| MN 15 10/14 | 10 | 14 | 2 |

| MN 20 20/7 | 20 | 7 | 2 |

| MN 20 20/14 | 20 | 14 | 2 |

| MN 25 30/7 | 30 | 7 | 2 |

| MN 30/60/7 | 60 | 7 | 2 |

| MN 30 60/14 | 60 | 14 | 3 |

| MN 35 90/7 | 90 | 7 | 2 |

| MN 35 90/14 | 90 | 14 | 3 |

| MN 40 50/7 | 50 | 7 | 3 |

| MN 40 140/7 | 140 | 7 | 3 |

| MN 40 140/20 | 140 | 20 | 4 |

| MN 45 120/7 | 120 | 7 | 4 |

| MN 47/190/7 | 190 | 7 | 4 |

| MN 50 120/10 | 120 | 10 | 4 |

| MN 55 200/10 | 200 | 10 | 5,5 |

| MN 57 450/7 | 450 | 7 | 5,5 |

| MN 60 370/10 | 370 | 10 | 7,5 |

| MN 60 370/14 | 370 | 14 | 7,5 |

| MN 67 680/7 | 680 | 7 | 12,5 |

| MN 80 520/14 | 520 | 10 | 10 |

| MN 87 960/7 | 960 | 7 | 15 |

| MN 120 870/12 | 870 | 10 | 15 |

| MN 127 1300/7 | 1300 | 7 | 15 |

| MN 200 1230/14 | 1230 | 10 | 15 |

| MN 207 2100/7 | 2700 | 7 | 20 |

| MN SERIES - Twin screw geometry | |||

|---|---|---|---|

| TYPE | CAPACITY l/min. | HEAD bar | POWER HP |

| MN 23 80/7 | 50 | 7 | 3 |

| MN 33 160/7 | 130 | 7 | 4 |

| MN 43 300/10 | 260 | 10 | 5,5 |

| MN 53 410/10 | 330 | 10 | 5,5 |

| MN 63 750/10 | 470 | 10 | 10 |

| MN 83 800/14 | 600 | 10 | 12,5 |

| MN 123 830/12 | 750 | 12 | 15 |

| The technical characteristics of the MN and MNT series are the same. | |||

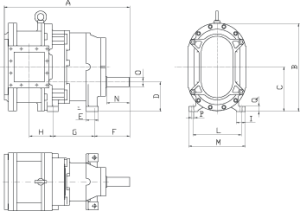

| PUMP DIMENSIONS (A) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TYPE | A | B | C | D | E | F | G | H | I | L | M | N |

| MN 10 3/5 | 545 | 140 | 120 | 1/2'' | 140 | 250 | -- | 75 | 230 | 120 | 150 | 140 |

| MN 15 10/7 | 919 | 250 | 120 | 3/4'' | 140 | 500 | 164 | 75 | 230 | 120 | 150 | 200 |

| MN 15 10/14 | 1003 | 333 | 120 | 3/4'' | 140 | 500 | 248 | 75 | 230 | 120 | 150 | 200 |

| MN 20 20/7 | 940 | 270 | 120 | 3/4'' | 140 | 500 | 185 | 75 | 230 | 120 | 150 | 200 |

| MN 20 20/14 | 1045 | 375 | 120 | 3/4'' | 140 | 500 | 290 | 75 | 230 | 120 | 150 | 200 |

| MN 23 80/7 | 1276 | 746 | 130 | 1'' | 458 | 530 | 376 | 297 | 90 | 110 | 150 | 100 |

| MN 25 30/7 | 1020 | 350 | 120 | 1'' | 140 | 500 | 285 | 75 | 230 | 120 | 150 | 200 |

| MN 30 60/7 | 980 | 310 | 120 | 1'' | 140 | 500 | 245 | 75 | 230 | 120 | 150 | 200 |

| MN 35 90/7 | 1030 | 350 | 120 | 1''1/4 | 140 | 500 | 280 | 75 | 230 | 120 | 150 | 200 |

| MN 37 100/5 | 1134 | 454 | 120 | 1''1/4 | 140 | 500 | 384 | 75 | 230 | 120 | 150 | 140 |

| PUMP DIMENSIONS (B) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TYPE | A | B | C | D | E | F | G | H | I | L | M | N |

| MN 30 60/14 | 1420 | 890 | 130 | 165 | 458 | 530 | 520 | 297 | 90 | 110 | 150 | 100 |

| MN 35 90/14 | 1500 | 970 | 130 | 165 | 458 | 530 | 600 | 297 | 90 | 110 | 150 | 100 |

| MN 40 50/7 | 1340 | 810 | 130 | 165 | 458 | 530 | 450 | 297 | 90 | 110 | 150 | 100 |

| MN 40 140/7 | 1290 | 760 | 130 | 165 | 458 | 530 | 390 | 297 | 90 | 110 | 150 | 100 |

| MN 40 140/20 | 1500 | 970 | 130 | 165 | 458 | 530 | 600 | 297 | 90 | 110 | 150 | 100 |

| MN 45 120/7 | 1300 | 770 | 130 | 165 | 458 | 530 | 400 | 297 | 90 | 110 | 150 | 100 |

| MN 47 190/7 | 1490 | 960 | 130 | 165 | 458 | 530 | 590 | 297 | 90 | 110 | 150 | 100 |

| MN 50 120/10 | 1340 | 810 | 130 | 165 | 458 | 530 | 445 | 297 | 90 | 110 | 150 | 100 |

| MN 55 200/10 | 1350 | 820 | 130 | 165 | 458 | 530 | 455 | 297 | 90 | 110 | 150 | 100 |

| MN 57 450/7 | 1600 | 1071 | 130 | 200 | 478 | 530 | 697 | 307 | 90 | 110 | 150 | 100 |

| MN 60 370/10 | 1771 | 1080 | 160 | 200 | 650 | 681 | 620 | 500 | 60 | 140 | 200 | 110 |

| MN 60 370/14 | 1871 | 1190 | 160 | 200 | 650 | 681 | 730 | 500 | 60 | 140 | 200 | 110 |

| MN 67 680/7 | 2060 | 1380 | 160 | 200 | 620 | 681 | 920 | 500 | 60 | 140 | 200 | 110 |

| MN 80 520/14 | 1871 | 1190 | 160 | 200 | 650 | 681 | 730 | 500 | 60 | 140 | 200 | 110 |

| MN 87 960/7 | 2181 | 1500 | 160 | 200 | 650 | 681 | 1040 | 500 | 60 | 140 | 200 | 110 |

| MN 120 870/12 | 2140 | 1250 | 160 | 200 | 710 | 890 | 940 | 500 | 60 | 140 | 200 | 150 |

| MN 127 1300/7 | 2533 | 1643 | 160 | 220 | 710 | 890 | 953 | 560 | 60 | 140 | 200 | 150 |

| MN 200 1230/14 | 2200 | 1310 | 160 | 220 | 710 | 890 | 1010 | 560 | 60 | 140 | 200 | 150 |

| MN 207 2100/7 | 2660 | 1770 | 160 | 220 | 710 | 890 | 1470 | 560 | 60 | 140 | 200 | 150 |

| TYPE | A | B | C | D | E | F | G | H | I | L | M | N |

| MN 33 160/7 | 1322 | 792 | 130 | 165 | 458 | 530 | 427 | 297 | 90 | 110 | 150 | 100 |

| MN 43 300/10 | 1383 | 853 | 130 | 165 | 470 | 530 | 488 | 307 | 90 | 110 | 150 | 100 |

| MN 53 410/10 | 1390 | 860 | 130 | 165 | 470 | 530 | 495 | 307 | 90 | 110 | 150 | 100 |

| MN 63 750/10 | 1813 | 1122 | 160 | 165 | 650 | 681 | 662 | 500 | 60 | 140 | 200 | 110 |

| MN 83 800/14 | 1871 | 1190 | 160 | 200 | 650 | 681 | 730 | 500 | 60 | 140 | 200 | 110 |

| MN 123 830/12 | 1930 | 1250 | 160 | 200 | 710 | 890 | 940 | 560 | 60 | 140 | 200 | 150 |

| Mod. MN 60, MN 80, MN 120 and MN 200 the upper flange measures 170x170 mm. N.B.: The above measurements are indicative only and can be varied at the manufacturer's discretion. |

||||||||||||

Gallery

Features

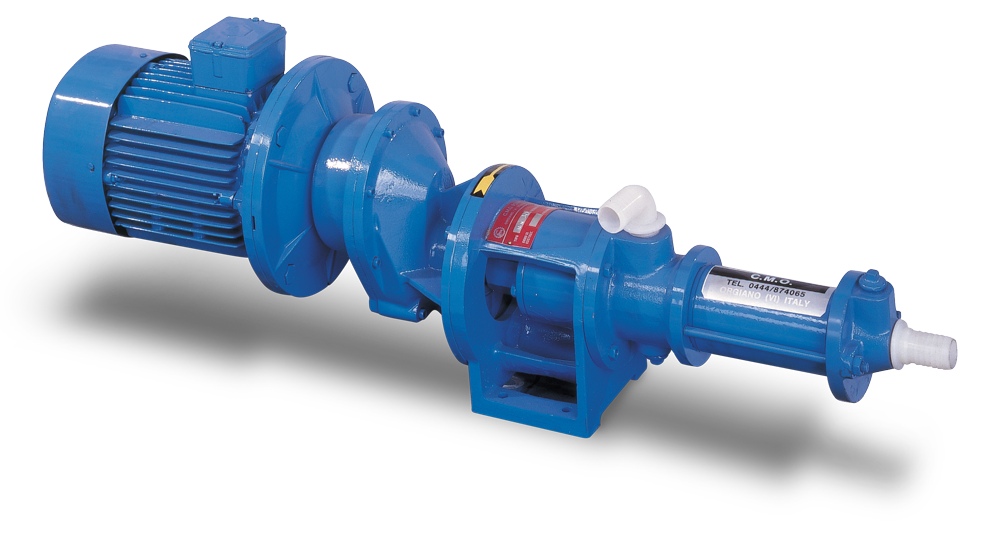

The MN series pumps belong to the rotating positive-displacement pump category. The MN series has been perfected with the aim of achieving maximum performance in line with such compact dimensions and a highly competitive price.

The reduced weight and compact dimensions allow this pump to be used in restricted spaces and in situations that are not particularly demanding.

Construction and technical characteristics

The flow rate varies according to the rotor pitch. The MN series covers a flow rate that ranges from 3.3 to 2700 l/min. The pressure varies from 0 to 14 bar, according to the length of the stator.

The parts in contact are made from thick chrome plated steel or 304 – 316l stainless steel according to the product to be pumped. The seal is either mechanical or gland. The stators are made from natural or different mixes of synthetic rubber (viton, silicon, perbunan, etc.). Special materials are available upon request.

The support is directly connected to the gearmotor or the variable speed drive.

Field of use

Thanks to the technical devices used and the unique operation mechanism, these pumps guarantee maximum performance when pumping must, grape clusters, fruit juices, jams, marmalades, oils, acid, adhesives, cellular cement marble sludge, lime putty, etc.

When pumping fluids with viscosity and/or abrasion levels that are different from water, it is advisable never to reach the limit pressure and flow rate values given in the table.

For the pump to work well, we recommend making sure that no air is being sucked in and that the fluid to be pumped is continually available in order to prevent the pump from working dry. The values given in the table refer to tests carried out using fluids with characteristics similar to water.

Flow rate curves

Technical data

| LB SERIES | |||

|---|---|---|---|

| TYPE | CAPACITY m3/h | SPEED r/min | HEAD bar |

| LB 70 | 50-35 | 150-650 | 10 |

| LB 140 | 20-70 | 150-650 | 8 |

| LB 150 | 35-135 | 150-650 | 10 |

| LB SERIES | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TYPE | A | B | C | D | E | F | G | H | I | L | M | N | O | P |

| LB 70 | 477 | 403 | 203 | 132 | 56 | 137 | 190 | 73 | 46 | 220 | 257 | 80 | 42 | 15 |

| LB 140 | 547 | 403 | 203 | 132 | 56 | 137 | 190 | 108 | 46 | 220 | 257 | 80 | 42 | 15 |

| LB 150 | 618 | 568 | 260 | 164 | 56 | 153 | 220 | 121 | 327 | 290 | 327 | 80 | 55 | 15 |