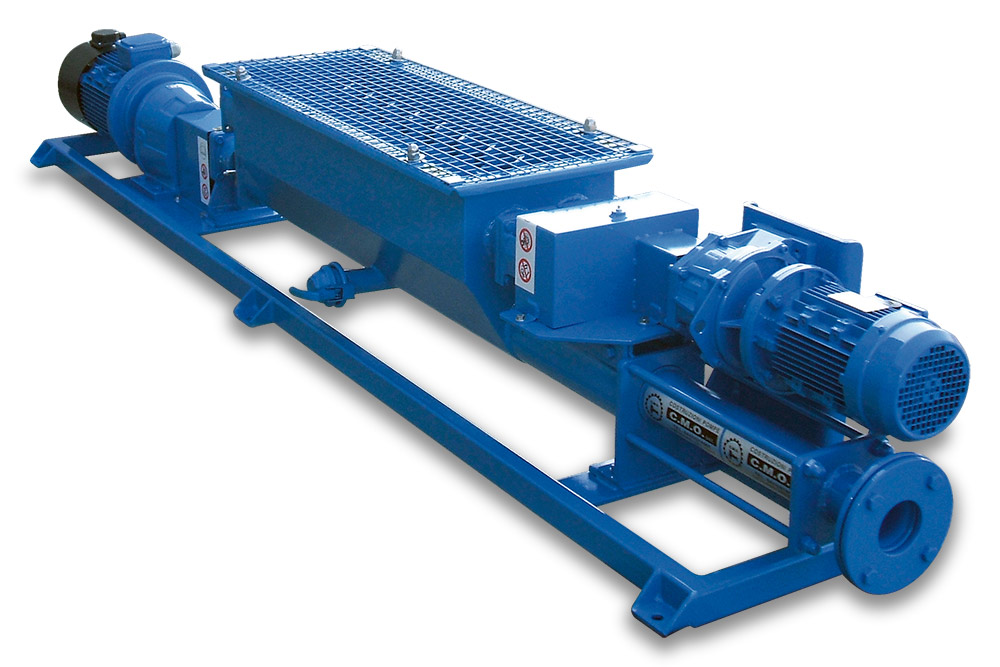

PS | PST Series

-

Features

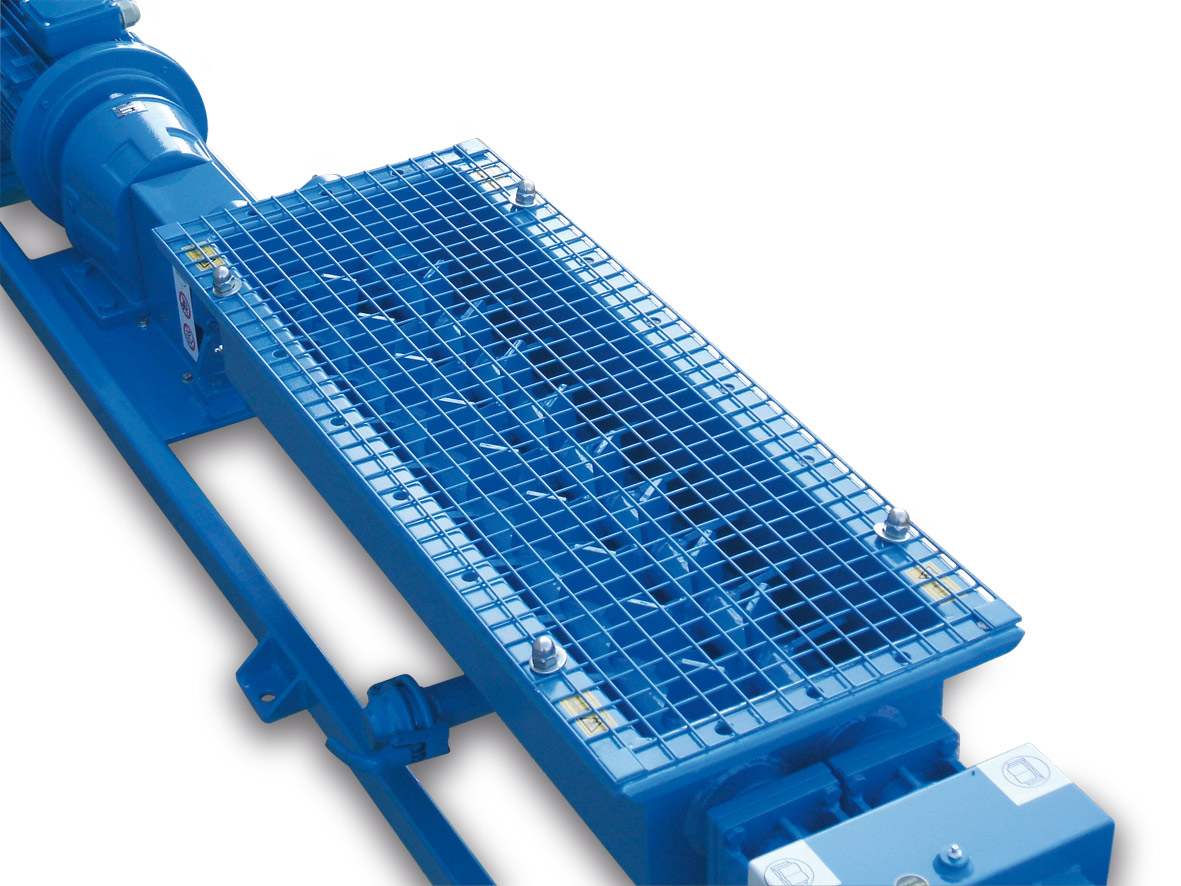

The CMO pumps with worm feed screw belong to the rotating positive-displacement pump category. With simple construction, the pumps are intended above all for pumping dense and/or viscous fluids.Construction and technical characteristics

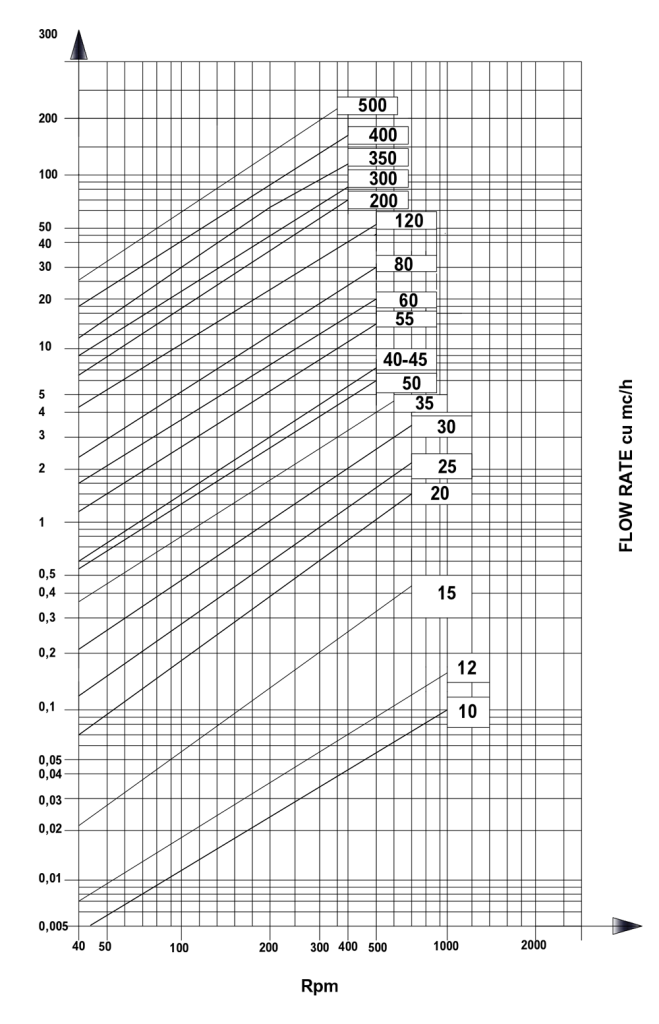

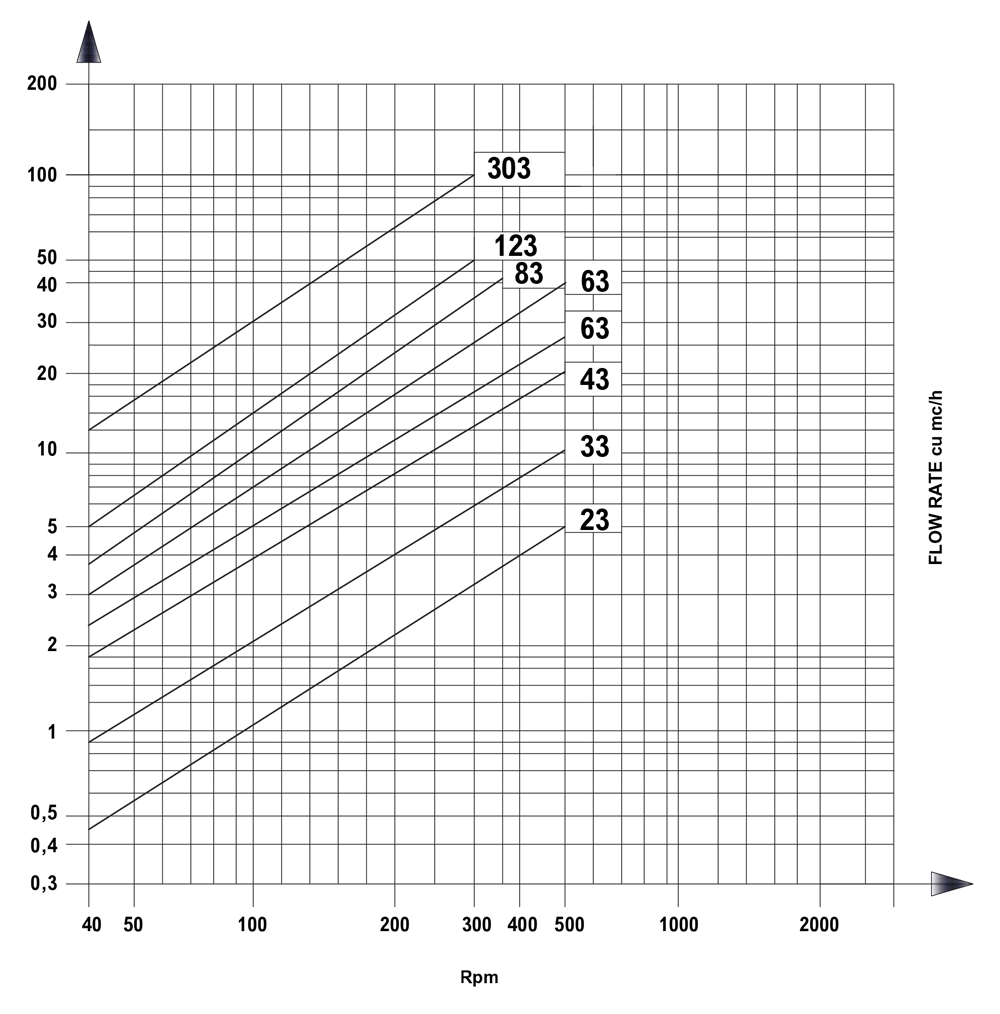

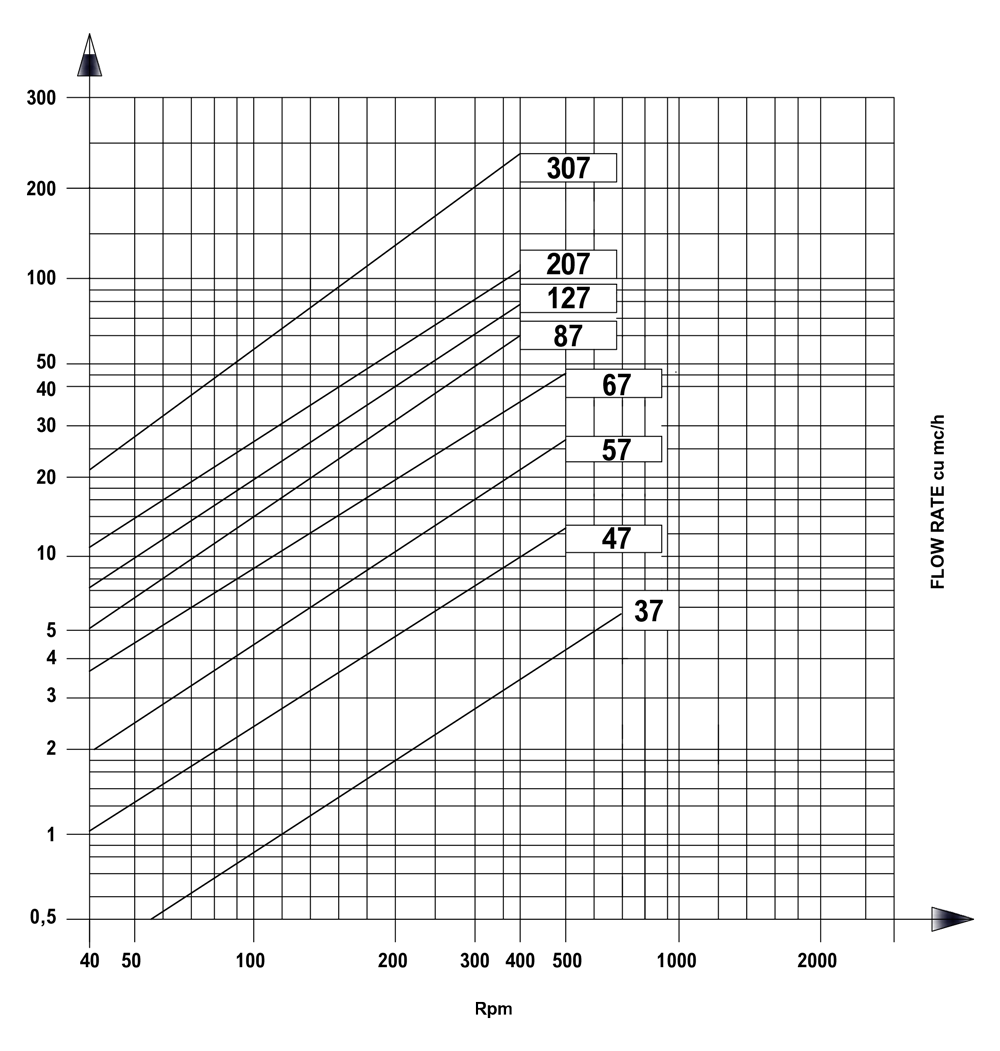

The capacity varies depending on the rotor step. The PS series covers a capacity range from 50 to 4000 l/min. The pressure varies with the length of the stator from 0 to 30 bar.

The parts in contact with the liquid are constructed in various materials, depending on the fluid to be pumped. The rotating parts are normally in casehardening or chromium-plated steel or in stainless steel 304 or 316. The stators are constructed in natural or synthetic rubber in different mixes (Viton, Silicon, Perbunan, etc.). Specific materials can be used on request.Field of use

The applications for this type of pump are virtually infinite, due its special construction, the materials used, the technical measures adopted and the singular working mechanism guarantee maximum performance whether pumping brackish water, stall waste, unicellular cement, marble sludge, lime putty, synthetic resins, foundry sludge, etc. When pumping fluids with density and/or abrasion characteristics different to those of water, it is recommended never to reach the pressure limit and capacity values expressed in the table.

For correct function of the pump, it is recommended to check that air is not being suctioned and that the supply of fluid to be pumped is constant to avoid the pump turning dry.

The values featured in the table refer to tests performed with fluids with characteristics similar to those of water.

-

Gallery

-

Technical data

PS SERIES TYPE CAPACITY l/min. HEAD bar POWER HP PS 40 50/7 50 7 3 PS 40 140/7 140 7 3 PS 40 140/20 140 20 4 PS 45 120/7 120 7 4 PS 47 190/7 190 7 4 PS 50 120/10 120 10 4 PS 50 120/30 120 30 7,5 PS 55 200/10 200 10 5,5 PS 55 200/26 200 26 7,5 PS 57 450/7 450 7 5,5 PS 60 370/10 370 10 7,5 PS 60 370/14 370 14 7,5 PS 60 370/20 370 20 10 PS 60 370/26 370 26 10 PS 67 680/7 680 7 12,5 PS 80 520/14 520 14 10 PS 80 520/30 520 30 15 PS 87 960/7 960 7 15 PS 120 870/12 870 12 15 PS 120 870/26 870 25 25 PS 127 1300/7 1300 7 15 PS 200 1230/14 1230 14 20 PS 200 1230/26 1230 26 30 PS 207 2100/7 2700 7 20 PS 300 1400/14 1400 14 30 PS 307 4000/7 4000 7 60 PS 350 2000/14 2000 14 30 PS 400 2800/10 2800 10 30 PS 500 3500/10 3500 10 60 PS SERIES - Twin screw geometry TYPE CAPACITY l/min. HEAD bar POWER HP PS 33 160/7 130 7 4 PS 43 300/10 260 10 5,5 PS 53 410/10 330 10 5,5 PS 63 750/10 470 10 10 PS 83 800/14 600 14 12,5 PS 123 830/12 750 12 15 PS 303 1600/14 1500 14 30 The technical characteristics of the PS and PST series are the same.

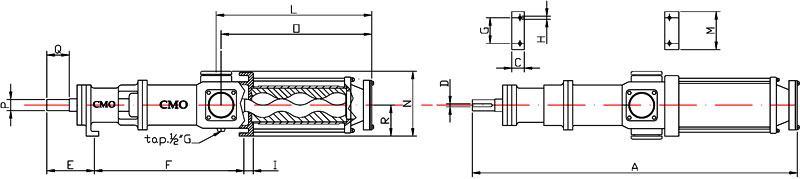

PS SERIES TYPE A B C D E F G H I L M N O P Q R PS 40 50/7 965 540 60 10 120 470 120 15 30 430 160 270 430 32 65 150 PS 40 140/7 920 540 60 10 120 470 120 15 30 390 160 270 390 32 65 150 PS 40 140/20 1130 540 60 10 120 470 120 15 30 590 160 270 590 32 65 150 PS 45 120/7 930 540 60 10 120 470 120 15 30 400 160 270 400 32 65 150 PS 47 190/7 1130 540 60 10 120 470 120 15 30 590 160 270 590 32 65 150 PS 50 120/10 950 540 60 10 120 470 120 15 30 430 160 270 430 32 65 150 PS 50 120/30 1240 540 60 10 120 470 120 15 30 700 160 270 700 32 65 150 PS 55 200/10 960 540 60 10 120 470 120 15 30 440 160 270 440 32 65 150 PS 55 200/26 1260 540 60 10 120 470 120 15 30 725 160 270 725 32 65 150 PS 57 450/7 1200 540 60 10 120 470 120 15 30 680 160 270 680 32 65 150 PS 60 370/10 1300 740 65 10 175 660 140 18 40 620 200 270 550 32 75 140 PS 60 370/14 1410 740 65 10 175 660 140 18 40 720 200 280 660 38 75 140 PS 60 370/20 1540 740 65 10 175 660 140 18 40 850 200 280 800 38 75 140 PS 60 370/26 1650 740 65 10 175 660 140 18 40 960 200 280 900 38 75 140 PS 67 680/7 1600 740 65 10 175 660 140 18 40 920 200 280 860 38 75 140 PS 80 520/14 1410 740 65 10 175 660 140 18 40 720 200 280 660 38 75 140 PS 80 520/30 1850 740 65 10 175 660 140 18 40 1160 200 280 1100 38 75 140 PS 87 960/7 1720 740 65 10 175 660 140 18 40 1030 200 280 970 38 75 140 PS 120 870/12 1480 800 70 10 180 720 140 18 40 940 200 300 660 38 75 140 PS 120 870/26 1920 800 70 10 180 720 140 18 40 1370 200 300 1090 38 75 140 PS 127 1300/7 1870 800 70 10 180 720 140 18 40 1320 200 300 1040 38 75 140 PS 200 1230/14 1560 800 70 10 180 720 140 18 40 1010 200 300 730 38 75 140 PS 200 1230/26 2060 800 70 10 180 720 140 18 40 1510 200 300 1230 38 75 140 PS 207 2100/7 2020 800 70 10 180 720 140 18 40 1450 200 300 1180 38 75 140 PS 300 1400/14 1600 860 70 12 180 720 150 18 50 890 240 390 830 42 78 160 PS 307 4000/7 2800 1315 84 14 195 1190 270 22 65 1880 330 500 - 70 100 245 PS 350 2000/14 1650 860 70 12 180 720 150 18 50 940 240 390 880 42 78 160 PS 400 2800/10 2020 860 70 12 180 720 150 18 50 1380 240 390 1320 42 78 160 PS 500 3500/10 2350 1315 84 14 195 1190 270 22 65 1430 330 500 - 70 100 245 PS SERIES - Twin screw geometry TYPE A B C D E F G H I L M N O P Q R PS 33 160/7 935 540 60 10 120 470 120 15 30 410 160 270 410 32 150 220 PS 43 300/10 990 540 60 10 120 470 120 15 30 470 160 270 470 32 150 220 PS 53 410/10 1000 540 60 10 120 470 120 15 30 480 160 270 480 32 150 220 PS 63 750/10 1345 740 60 10 175 660 140 18 40 665 200 280 595 38 140 260 PS 83 800/14 1410 740 65 10 175 660 140 18 40 720 200 280 660 38 75 140 PS 123 830/12 1480 800 70 10 180 720 140 18 40 940 200 300 660 38 140 260 PS 303 1600/14 1675 860 70 12 180 780 150 18 50 965 240 300 905 42 160 300 The above measurements are indicative only and can be varied at the manufacturer's discretion.