Features

SINGLE SCREW PUMP

The worm screw CMO pump belongs to the rotating positive-displacement pump category. Its main components are:

- Rotor normally in chromium-plated steel or stainless steel.

- Stator composed of a steel container inside which a seat in rubber (or other material depending on requirements or working conditions) is vulcanised and suitably treated with an antacid material that can be wiped.

The stator-rotor unit is delimited by a sealing ring that, during the rotation movement, prevents air from entering, thereby guaranteeing the positive-displacement suction capability.

The CMO pump features an extremely simple and precise construction, qualities which guarantee correct function of the pump. The conductor shaft is supported by two ball bearings and is sealed at the pump body by an efficient sealing system that the Client can choose as an optional.

The CMO pump features an extremely simple and precise construction, qualities which guarantee correct function of the pump. The conductor shaft is supported by two ball bearings and is sealed at the pump body by an efficient sealing system that the Client can choose as an optional.

The rotating movement of the conductor shaft is transmitted to the rotor by means of a homokinetic drive system, safeguarded by strong rubber protections.

In order to assist use of our pumps, we have installed the suction tubing attachment on three sides of the pump body to be used as required.

The CMO pump is used to resolve multiple application pumping problems.

For example:

- In the AGRICULTURAL sector for removing stall waste, diluted droppings, for irrigation, etc.

- In the CHEMICAL sector for pumping products such as: synthetic resins, magnesia, lye, pastes, varnish, paint, acid, wax, fungicides, petrol, oil, printing inks, etc.

- In the BUILDING sector for pumping unicellular cement, lime putty, etc.

- In MARBLE SAWMILLS for eliminating marble sludges.

- In TANNERIES, for removing water with tanning residues, oils, tannin, etc.

- In DEPURATION PLANTS for feeding centrifugal systems and filters, for conveying various sludges.

- In the FOOD INDUSTRY for conveying flour soaked with water, preserves, jams, sugar solutions, fruit juice, chocolate mixtures, glucose, honey, cream, milk, melted cheese, butter, dehumidified wines, bunches of grapes.

- In the PHARMACEUTICAL AND COSMETIC INDUSTRY for pumping various creams, toothpaste, soap, detergents, shampoo, hand soaps, etc.

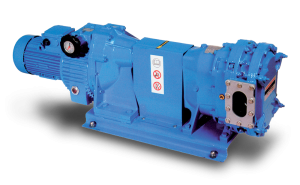

LOBE PUMP

The important characteristics of this type of pump are:

The important characteristics of this type of pump are:

- Compact size, just a little bigger than a rotor pump.

- Easy cleaning and maintenance. The rotors can be replaced without having to dismantle the piping.

- Double rotation: the suction connection can be positioned on the right or on the left.

The CMO lobe pump can be used in various fields:

- Agriculture: for expurging stable effluent, diluted excrement, etc.

- Marble saw mills: for eliminating marble sludge.

- Tanneries: for expurging water containing tanning deposits, etc.

- Purifying plants: for treating digested primary sludge.

- Building: cement bentonite, polystyrene, lime putty, etc.

- Drainage: for effluent or regenerating exhausted oils.