Author Archive

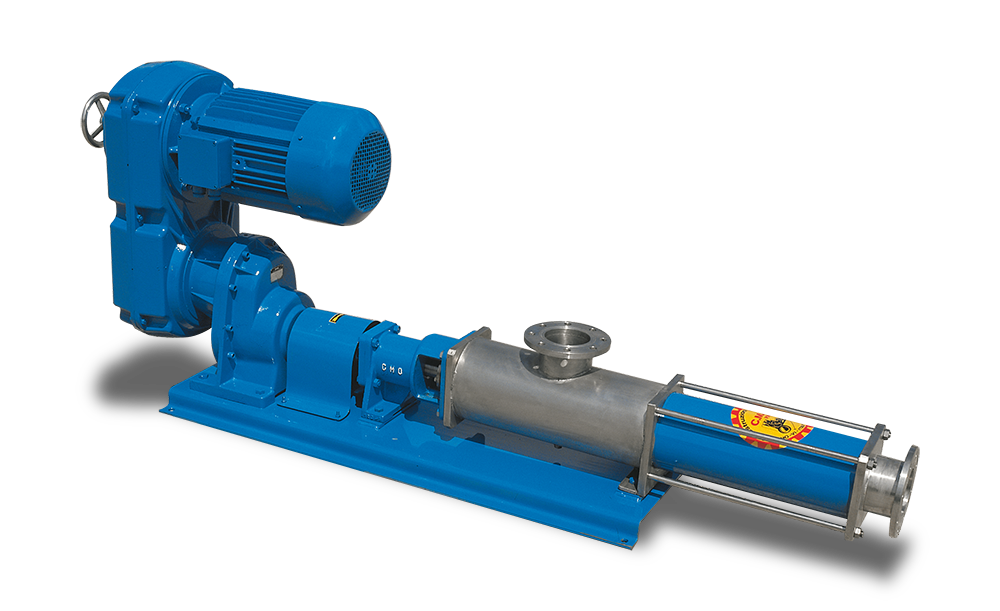

PS | PST Series

PT inox | PS inox | PST inox Series

-

Features

The CMO pumps with worm feed screw belong to the rotating positive-displacement pump category. With simple construction, the pumps are intended above all for pumping dense and/or viscous fluids.

Construction and technical characteristics

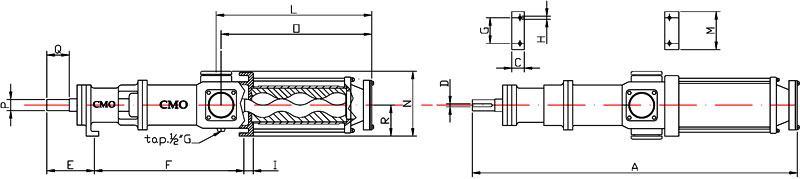

The capacity varies depending on the rotor step. The PS stainless steel series covers a capacity range from 50 to 4000 l/min, the PT stainless steel series from 50 to 1000 l/min with maximum rotation speed of 140 rpm or 200 rpm. The pressure varies with the length of the stator from 0 to 30 bar. The parts in contact with the liquid are constructed in various materials, depending on the fluid to be pumped. The rotating parts are normally in casehardening or chromium-plated steel or in stainless steel 304 or 316. The stators are constructed in natural or synthetic rubber in various mixes (Viton, Silicon, Perbunan, etc.). Specific materials can be used on request.

Field of use

The applications for this type of pump are virtually infinite due to its special construction, the materials used, the technical measures adopted and the singular working mechanism that guarantee maximum performance whether pumping must, bunches of grapes, fruit juices, meat extracts, jam, marmalade, acids, glues, oils, liquid soaps, detergents, etc.

When pumping fluids with density and/or abrasion characteristics different from those of water, it is recommended never to reach the pressure limit and capacity values expressed in the table.

For correct function of the pump, it is recommended to check that air is not being suctioned and that the supply of fluid to be pumped is constant to avoid the pump turning dry.

The values featured in the table refer to tests performed with fluids with characteristics similar to those of water. -

Gallery

-

Technical data

PS inox SERIES TYPE CAPACITY l/min. HEAD bar POWER HP PS 40 50/7 50 7 3 PS 40140/7 140 7 3 PS 40 140/20 140 20 4 PS 45 120/7 120 7 4 PS 47/190/7 190 7 4 PS 50 120/10 120 10 4 PS 50 120/30 120 30 7,5 PS 55 200/10 200 10 5,5 PS 55 200/26 200 26 7,5 PS 57 450/7 450 7 5,5 PS 60 370/10 370 10 7,5 PS 60 370/14 370 14 7,5 PS 60 370/26 370 26 10 PS 67 680/7 680 7 12,5 PS 80 520/14 520 14 10 PS 80 520/30 520 30 15 PS 87 960/7 960 7 15 PS 120 870/12 870 12 15 PS 120 870/26 870 25 25 PS 127 1300/7 1300 7 15 PS 200 1230/14 1230 14 20 PS 200 1230/26 1230 26 30 PS 207 2100/7 2700 7 20 PS 300 1400/14 1400 14 30 PS 307 4000/7 4000 7 60 PS 350 2000/14 2000 14 30 PS 400 2800/10 2800 10 30 PS 500 3500/10 3500 10 60 PS inox SERIES - Twin screw geometry TYPE CAPACITY l/min. HEAD bar POWER HP PS 33 160/7 130 7 4 PS 43 300/10 260 10 5,5 PS 53 410/10 330 10 5,5 PS 63 750/10 470 10 10 PS 83 800/14 600 14 12,5 PS 123 830/12 750 12 15 PS 303 1600/14 1500 14 30 The technical characteristics of the PS and PST series are the same. PT inox SERIES TYPE CAPACITY l/min. TURNS rpm/min. HEAD bar POWER HP PT 40 140/7 50 200 5 4 PT 55 200/7 84 200 7 4 PT 60 370/7 83 140 7 5,5 PT80 520/7 115 140 7 5,5 PT 120 870/7 230 140 7 5,5 PT 200 1230/7 430 140 7 7,5 PT 300 1400/7 500 140 7 12,5 PT 350 2000/7 670 140 7 15 PT 40 140/7 60 280 5 4 PT 55 200/7 120 280 7 4 PT 60 370/7 116 200 7 5,5 PT80 520/7 160 200 7 5,5 PT 120 870/7 2330 200 7 5,5 PT 200 1230/7 570 200 7 7,5 PT 300 1400/7 710 200 7 12,5 PT 350 2000/7 1000 200 7 15 PT inox SERIES - Twin screw geometry TYPE CAPACITY l/min. TURNS rpm/min. HEAD bar POWER HP PT 33 160/7 50 140 8 4 PT 43 300/10 80 140 7 5,5 PT 53 410/10 110 140 7 5,5 PT 63 750/10 183 140 7 5,5 PT 83 800/14 290 140 7 7,5 PT 123 830/12 340 140 7 7,5 PT 33 160/7 60 190 8 4 PT 43 300/10 116 190 7 5,5 PT 53 410/10 165 190 7 5,5 PT 63 750/10 230 190 7 5,5 PT 83 800/14 390 190 7 7,5 PT 123 830/12 490 190 7 7,5 The technical characteristics of the PS and PST series are the same. PT inox SERIES TYPE A B C D E F G H I L PT 40 140/7 490 440 410 1340 520 445 380 520 440 1050 PT 55 200/7 550 440 410 1400 520 445 380 520 440 1050 PT 60 370/7 730 750 410 1890 830 445 380 830 750 1050 PT 80 520/7 840 750 410 2000 830 445 380 830 750 1050 PT 120 870/7 890 750 495 2092 830 445 380 830 750 1050 PT 200 1230/7 950 750 495 2130 830 570 380 830 750 1050 PT 300 1400/7 980 750 540 2270 830 570 380 830 750 1050 PT 350 2000/7 980 750 520 2250 830 715 400 830 750 1050 PT inox SERIES - Twin screw geometry TYPE A B C D E F G H I L PT 33 160/5 530 440 410 1380 520 445 380 520 440 1050 PT 43 300/7 605 500 430 1535 730 445 380 730 650 1000 PT 53 410/7 610 500 430 1540 730 445 380 730 650 1000 PT 63 750/7 770 750 410 1930 830 445 380 830 750 1050 PT 83 800/7 840 750 540 2180 830 445 380 830 750 1050 PT 123 870/7 890 750 540 2180 830 445 380 830 750 1050 The above measurements are indicative only and can be varied at the manufacturer's discretion.

MN | MNT | MN inox | MNT inox Series

-

Features

The MN series pumps belong to the rotating positive-displacement pump category. The MN series has been perfected with the aim of achieving maximum performance in line with such compact dimensions and a highly competitive price.

The reduced weight and compact dimensions allow this pump to be used in restricted spaces and in situations that are not particularly demanding.Construction and technical characteristics

The flow rate varies according to the rotor pitch. The MN series covers a flow rate that ranges from 3.3 to 2700 l/min. The pressure varies from 0 to 14 bar, according to the length of the stator.

The parts in contact are made from thick chrome plated steel or 304 – 316l stainless steel according to the product to be pumped. The seal is either mechanical or gland. The stators are made from natural or different mixes of synthetic rubber (viton, silicon, perbunan, etc.). Special materials are available upon request.

The support is directly connected to the gearmotor or the variable speed drive.Field of use

Thanks to the technical devices used and the unique operation mechanism, these pumps guarantee maximum performance when pumping must, grape clusters, fruit juices, jams, marmalades, oils, acid, adhesives, cellular cement marble sludge, lime putty, etc.

When pumping fluids with viscosity and/or abrasion levels that are different from water, it is advisable never to reach the limit pressure and flow rate values given in the table.

For the pump to work well, we recommend making sure that no air is being sucked in and that the fluid to be pumped is continually available in order to prevent the pump from working dry. The values given in the table refer to tests carried out using fluids with characteristics similar to water. -

Gallery

-

Technical data

MN SERIES TYPE CAPACITY l/min. HEAD bar POWER HP MN 10 3/5 3.3 5 0,75 MN 15 10/7 10 7 1 MN 15 10/14 10 14 2 MN 20 20/7 20 7 2 MN 20 20/14 20 14 2 MN 25 30/7 30 7 2 MN 30/60/7 60 7 2 MN 30 60/14 60 14 3 MN 35 90/7 90 7 2 MN 35 90/14 90 14 3 MN 40 50/7 50 7 3 MN 40 140/7 140 7 3 MN 40 140/20 140 20 4 MN 45 120/7 120 7 4 MN 47/190/7 190 7 4 MN 50 120/10 120 10 4 MN 55 200/10 200 10 5,5 MN 57 450/7 450 7 5,5 MN 60 370/10 370 10 7,5 MN 60 370/14 370 14 7,5 MN 67 680/7 680 7 12,5 MN 80 520/14 520 10 10 MN 87 960/7 960 7 15 MN 120 870/12 870 10 15 MN 127 1300/7 1300 7 15 MN 200 1230/14 1230 10 15 MN 207 2100/7 2700 7 20 MN SERIES - Twin screw geometry TYPE CAPACITY l/min. HEAD bar POWER HP MN 23 80/7 50 7 3 MN 33 160/7 130 7 4 MN 43 300/10 260 10 5,5 MN 53 410/10 330 10 5,5 MN 63 750/10 470 10 10 MN 83 800/14 600 10 12,5 MN 123 830/12 750 12 15 The technical characteristics of the MN and MNT series are the same. PUMP DIMENSIONS (A) TYPE A B C D E F G H I L M N MN 10 3/5 545 140 120 1/2'' 140 250 -- 75 230 120 150 140 MN 15 10/7 919 250 120 3/4'' 140 500 164 75 230 120 150 200 MN 15 10/14 1003 333 120 3/4'' 140 500 248 75 230 120 150 200 MN 20 20/7 940 270 120 3/4'' 140 500 185 75 230 120 150 200 MN 20 20/14 1045 375 120 3/4'' 140 500 290 75 230 120 150 200 MN 23 80/7 1276 746 130 1'' 458 530 376 297 90 110 150 100 MN 25 30/7 1020 350 120 1'' 140 500 285 75 230 120 150 200 MN 30 60/7 980 310 120 1'' 140 500 245 75 230 120 150 200 MN 35 90/7 1030 350 120 1''1/4 140 500 280 75 230 120 150 200 MN 37 100/5 1134 454 120 1''1/4 140 500 384 75 230 120 150 140 PUMP DIMENSIONS (B) TYPE A B C D E F G H I L M N MN 30 60/14 1420 890 130 165 458 530 520 297 90 110 150 100 MN 35 90/14 1500 970 130 165 458 530 600 297 90 110 150 100 MN 40 50/7 1340 810 130 165 458 530 450 297 90 110 150 100 MN 40 140/7 1290 760 130 165 458 530 390 297 90 110 150 100 MN 40 140/20 1500 970 130 165 458 530 600 297 90 110 150 100 MN 45 120/7 1300 770 130 165 458 530 400 297 90 110 150 100 MN 47 190/7 1490 960 130 165 458 530 590 297 90 110 150 100 MN 50 120/10 1340 810 130 165 458 530 445 297 90 110 150 100 MN 55 200/10 1350 820 130 165 458 530 455 297 90 110 150 100 MN 57 450/7 1600 1071 130 200 478 530 697 307 90 110 150 100 MN 60 370/10 1771 1080 160 200 650 681 620 500 60 140 200 110 MN 60 370/14 1871 1190 160 200 650 681 730 500 60 140 200 110 MN 67 680/7 2060 1380 160 200 620 681 920 500 60 140 200 110 MN 80 520/14 1871 1190 160 200 650 681 730 500 60 140 200 110 MN 87 960/7 2181 1500 160 200 650 681 1040 500 60 140 200 110 MN 120 870/12 2140 1250 160 200 710 890 940 500 60 140 200 150 MN 127 1300/7 2533 1643 160 220 710 890 953 560 60 140 200 150 MN 200 1230/14 2200 1310 160 220 710 890 1010 560 60 140 200 150 MN 207 2100/7 2660 1770 160 220 710 890 1470 560 60 140 200 150 TYPE A B C D E F G H I L M N MN 33 160/7 1322 792 130 165 458 530 427 297 90 110 150 100 MN 43 300/10 1383 853 130 165 470 530 488 307 90 110 150 100 MN 53 410/10 1390 860 130 165 470 530 495 307 90 110 150 100 MN 63 750/10 1813 1122 160 165 650 681 662 500 60 140 200 110 MN 83 800/14 1871 1190 160 200 650 681 730 500 60 140 200 110 MN 123 830/12 1930 1250 160 200 710 890 940 560 60 140 200 150 Mod. MN 60, MN 80, MN 120 and MN 200 the upper flange measures 170x170 mm.

N.B.: The above measurements are indicative only and can be varied at the manufacturer's discretion.

PV | PV inox Series

-

Features

Construction and technical characteristics

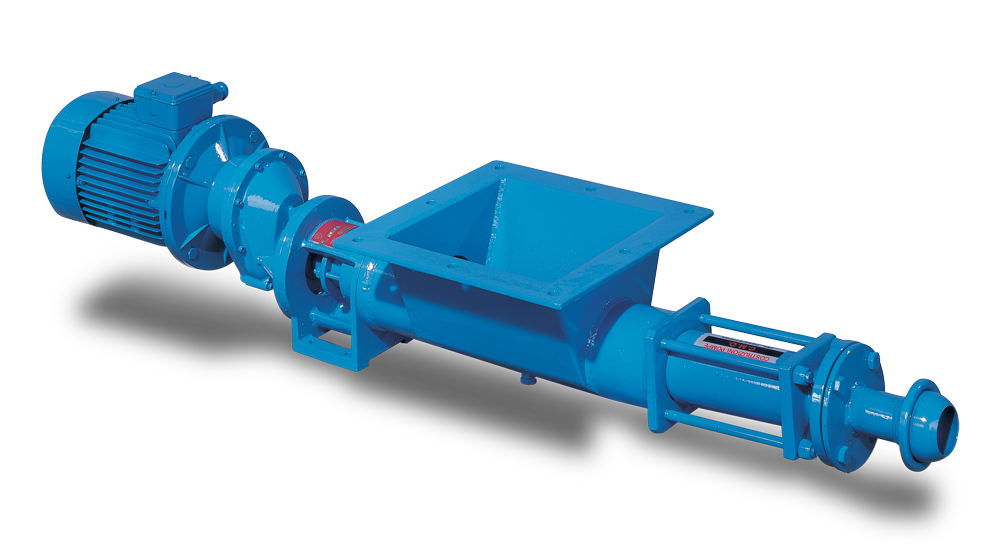

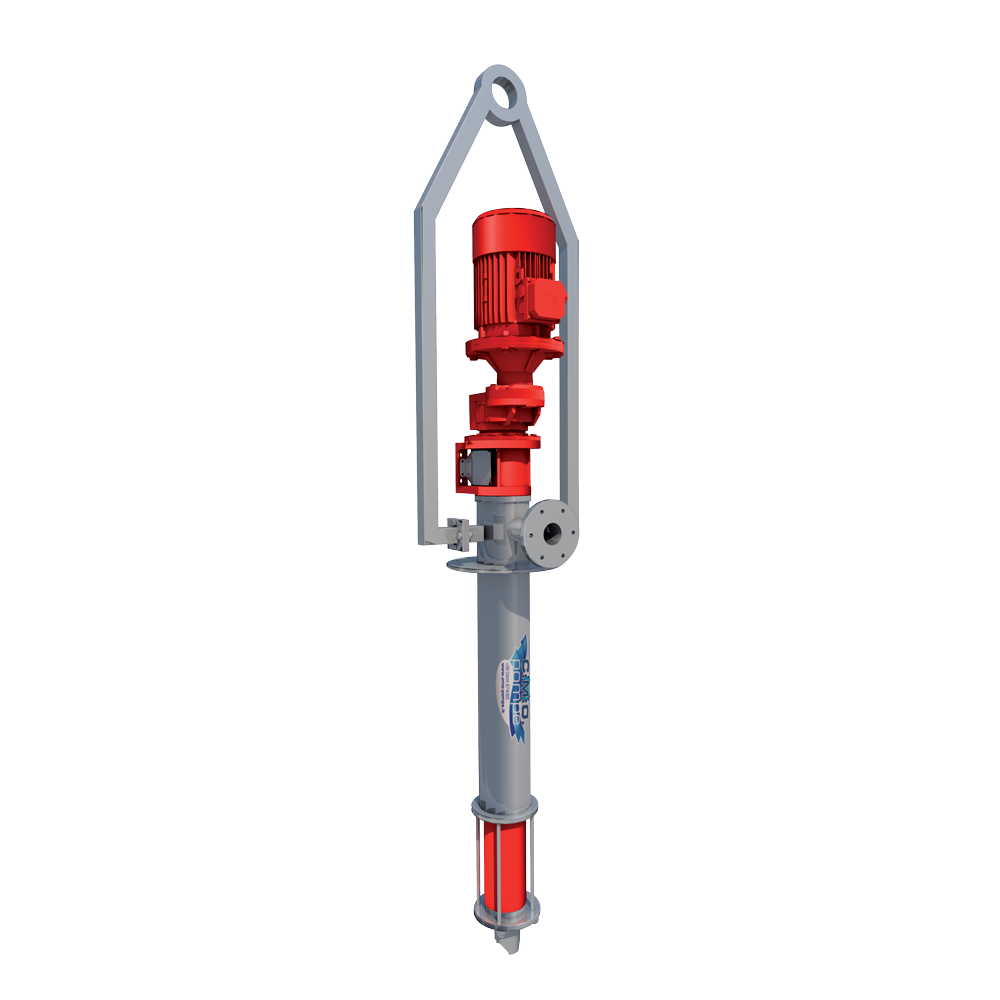

The “PV” series pump is a special type of semi-submersible single screw pump designed to work vertically instead of horizontally as the standard models do. Expressly designed to solve problems caused by sucking products inside tanks, sewers, cisterns, drums, wells, these pumps are distinguished by an elevated positive suction head created because the pumping compartment is directly inserted inside the product to be pumped.

The particular priming method also guarantees a good result with both abrasive and corrosive highly viscous liquids.

As with standard single screw pumps, the fields of application of “PV” series pumps are many in number: Agriculture, Chemicals, Building, Water Treatment, Food and Beverages (wine, preserves, oils, jams, cheese, etc.), Cosmetics, Pharmaceutical, etc. Field of use

Field of useThe numerous fields of application of this pump required a careful search for the most appropriate constructive materials and the best applications in order to cover every single client need and obtain the number of applications and settings required to guarantee “PV” series pumps the elevated flexibility for use in situations where other models are impractical.

-

Gallery

-

Technical data

PV SERIES TYPE FLOW RATE l/min. HEAD bar POWER HP PV 10 2/5

1,2

5

0,75

PV 12 3/5

2,5

5

0,75

PV 15 10/7

10

7

1

PV 15 10/14

10

14

2

PV 20 20/7

20

7

2

PV 20 20/14

20

14

2

PV 25 30/7

20

7

2

PV 30 60/7

30

7

2

PV 30 60/14

60

7

2

PV 35 90/7

90

7

2

PV 35 90/14

90

14

3

PV 37 100/7

100

5

2

PV 40 50/7

50

7

3

PV 40 140/7

140

7

3

PV 40 140/20

140

20

4

PV 45 120/7

120

7

4

PV 47/190/7

190

7

4

PV 50 120/10

120

10

4

PV 55 200/10

200

10

5,5

PV 57 450/7

450

7

5,5

PV 60 370/10

370

10

7,5

PV 60 370/14

370

14

7,5

PV 67 680/7

680

7

12,5

PV 80 520/14

520

10

10

PV 87 960/7

960

7

15

PV 120 870/12

870

10

15

PV 127 1300/7

1300

7

15

PV 200 1230/14

1230

10

15

PV 207 2100/7

2700

7

20

The flow rates indicated above regard the maximum rpm at 1 bar.

The pump’s overall dimensions and connections must be assessed when requesting an estimate.

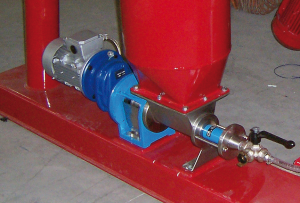

PI Series

-

Features

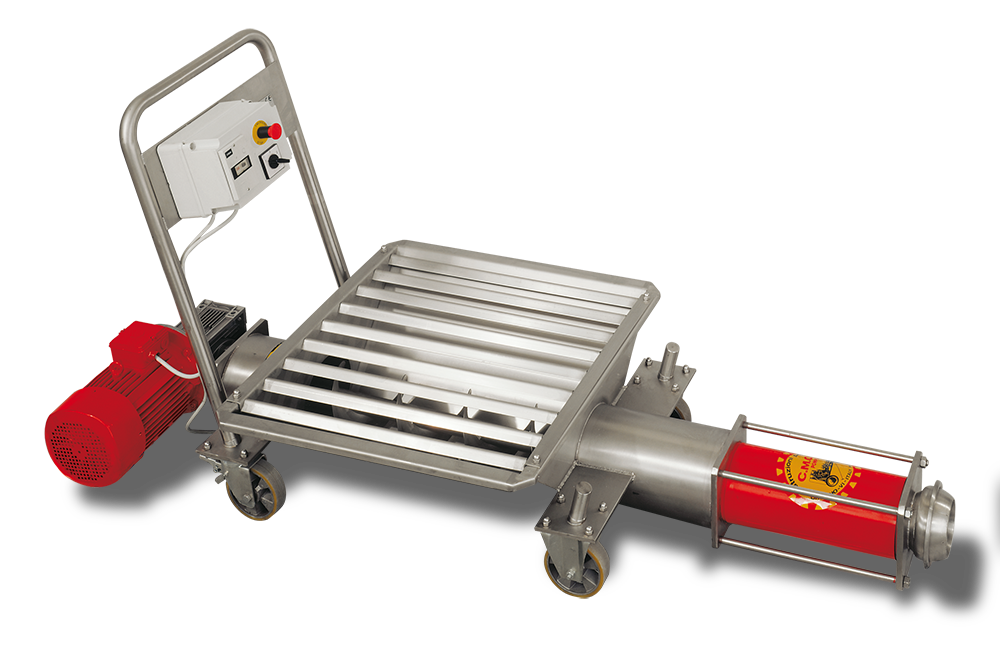

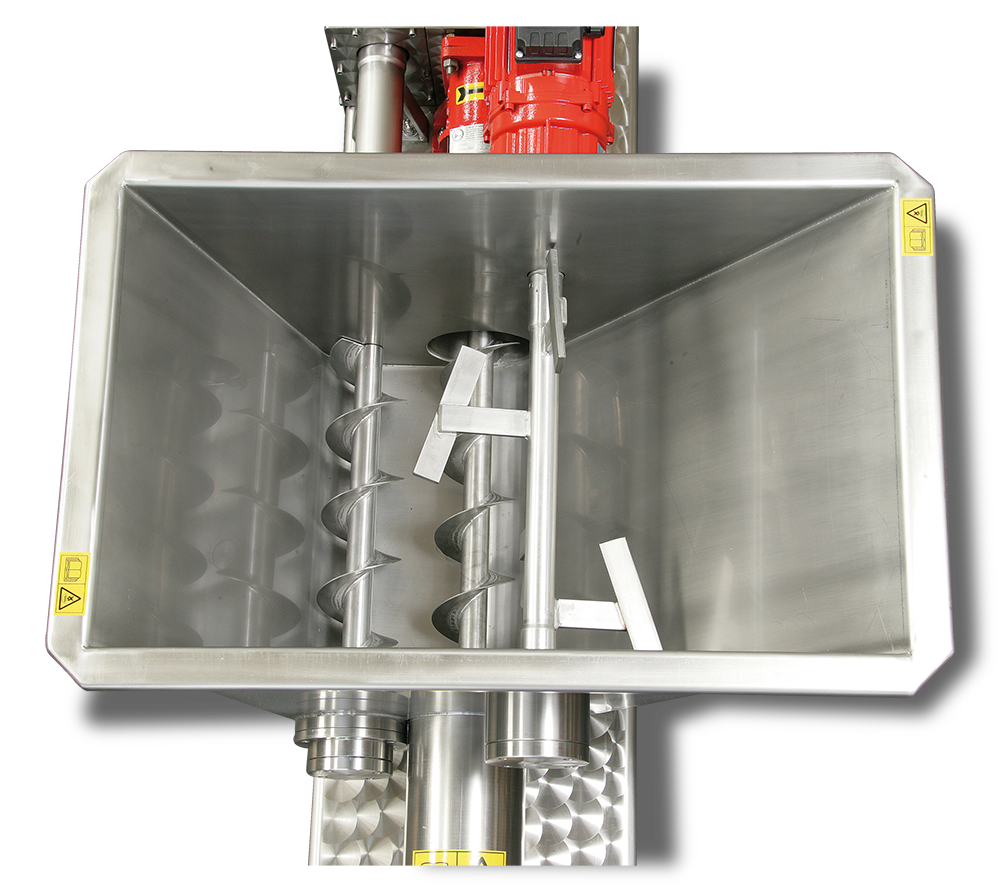

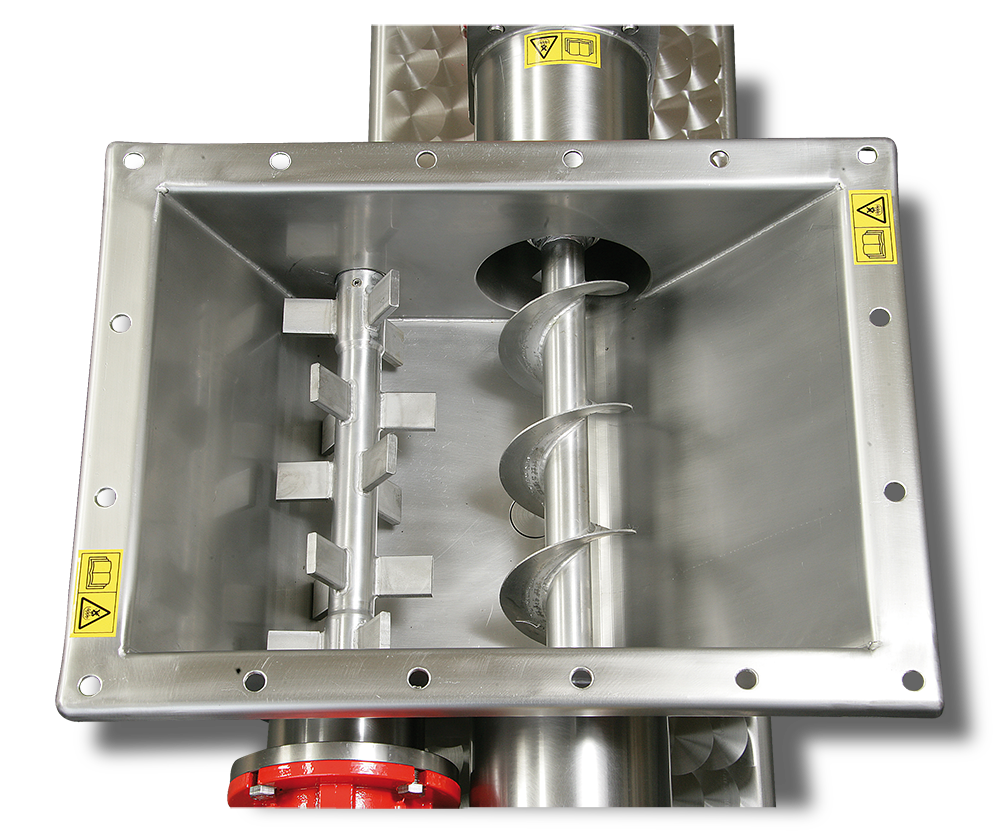

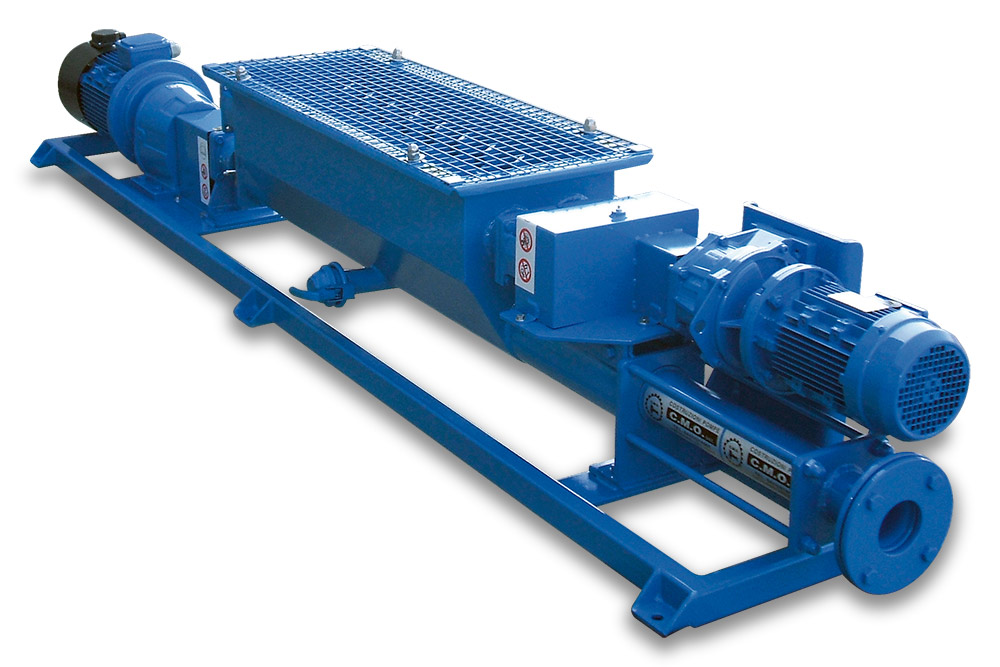

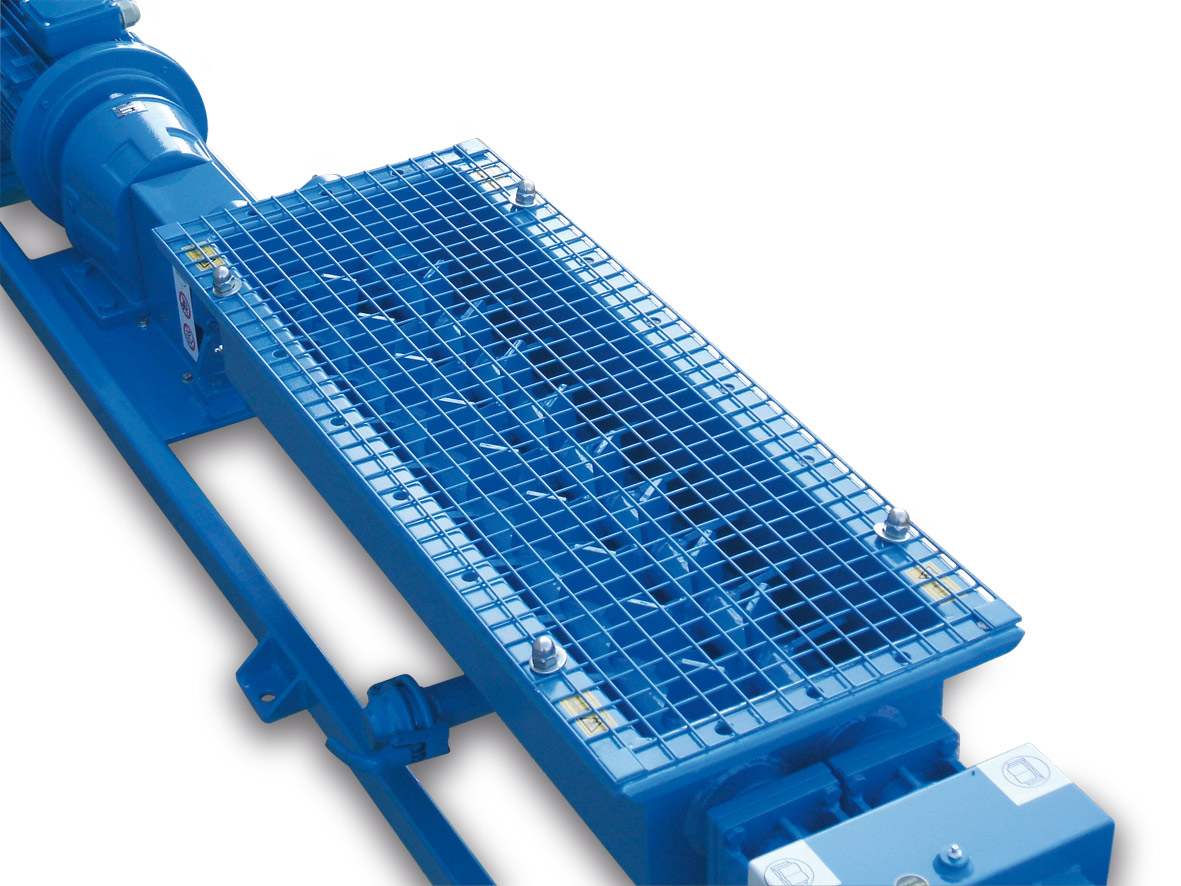

The C.M.O. PI series single screw pump was developed after years of working closely with the leading mixing machine manufacturers.

The C.M.O. PI series single screw pump was developed after years of working closely with the leading mixing machine manufacturers.

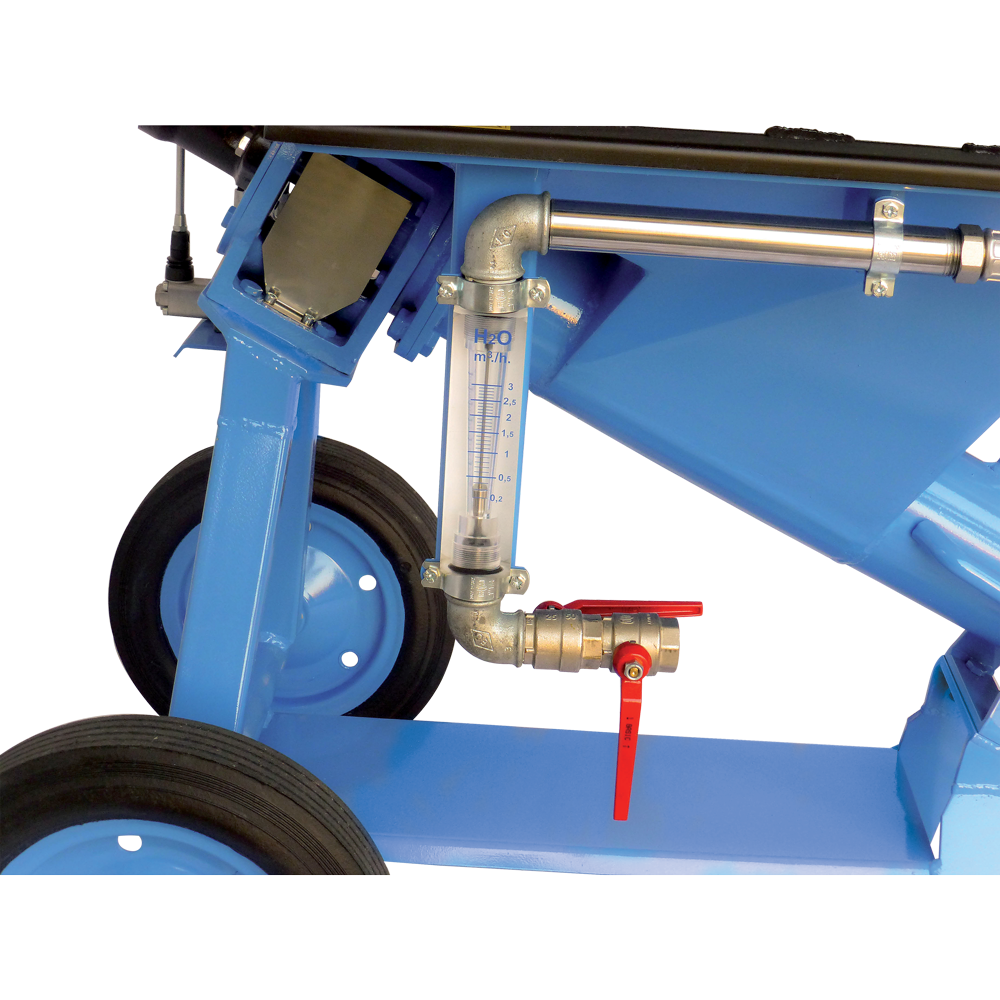

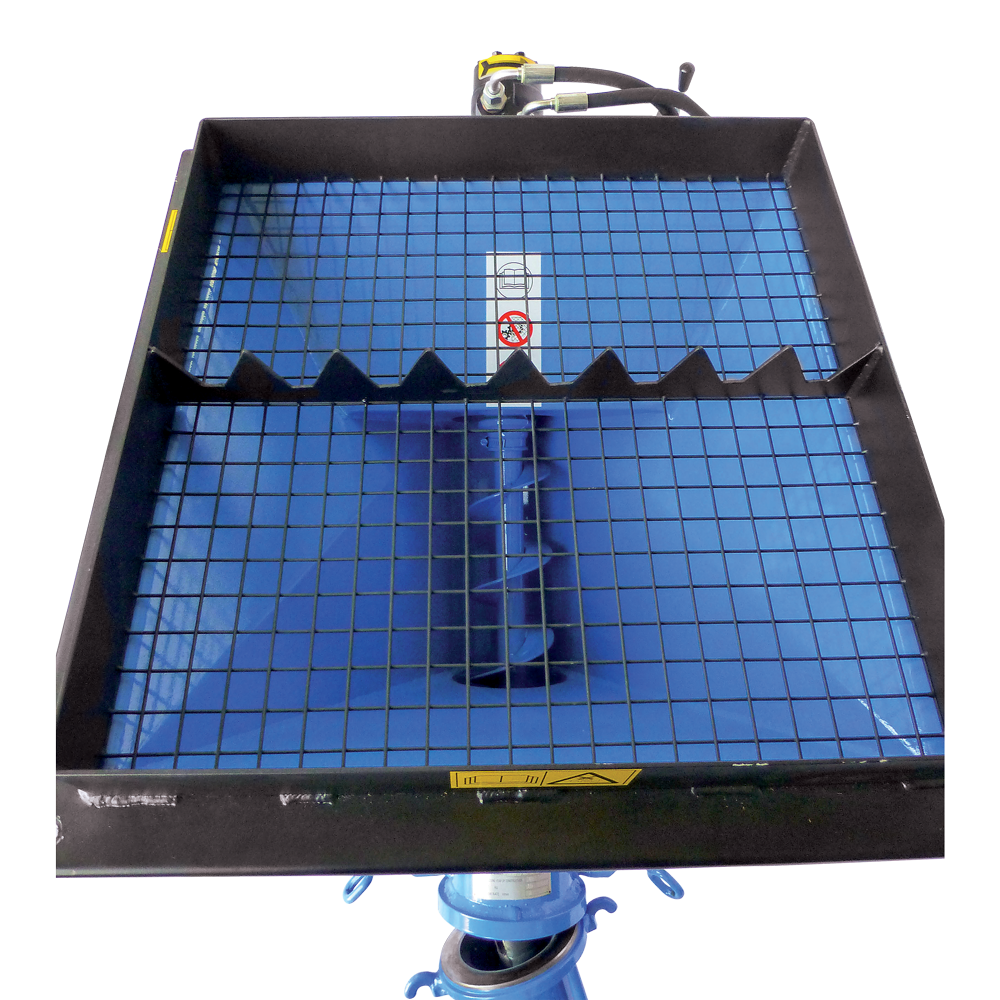

This machine permits the mixing of cement materials inside a special hopper with water and then to inject them directly at high pressures.

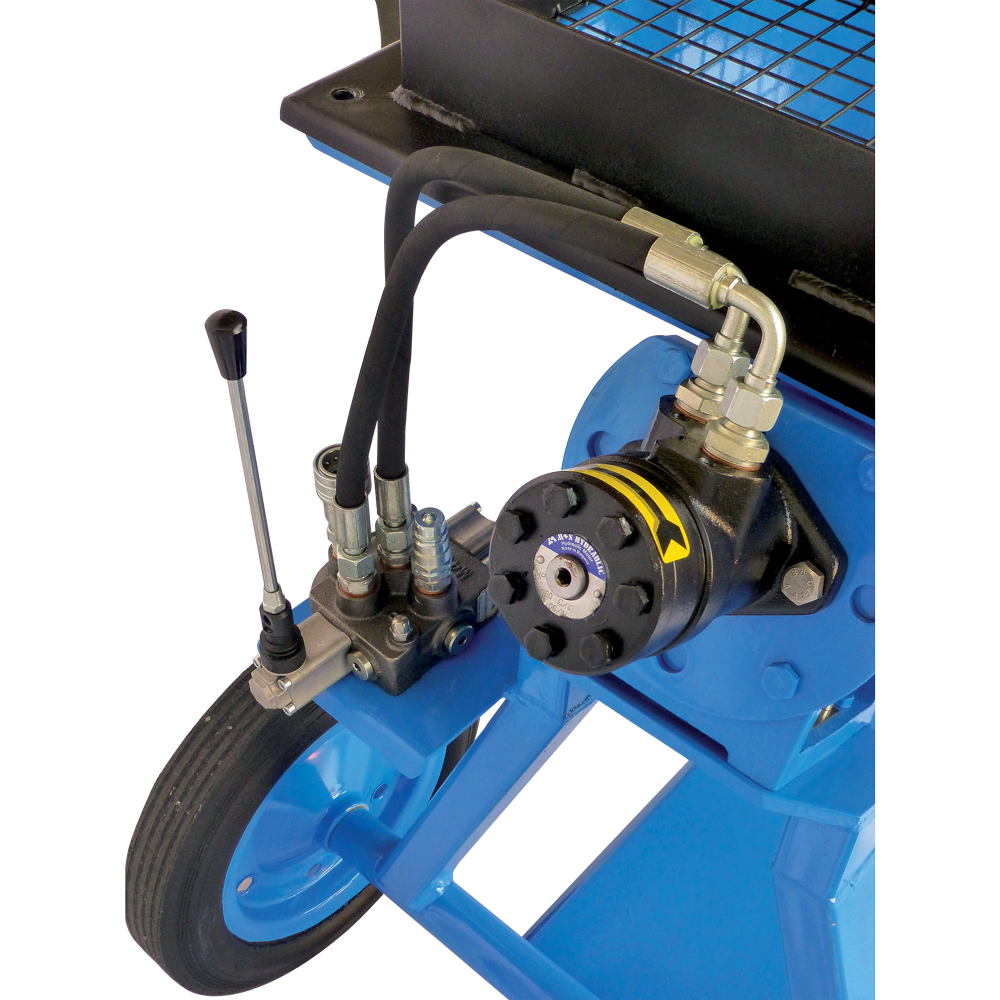

The light weight and the practicality of the trolley makes the pump particularly easy to manoeuvre even in the most restricted areas, whereas the capacious loading hopper, which is also provided with a sack breaker allows the machine to be directly installed beneath a silo.The guillotine coupling between the joint with the feeding screw and the rotor ensures the simple disassembly and the replacement of the stator, thanks also to the lateral closing hinges that ensure rapid removal of the pumping compartment whenever necessary. Because it can be completely disassembled, the internal parts of the machine in contact with the product can be easily and thoroughly cleaned.

The standard machine can be equipped with a hydraulic motor controlled by a manual distributor that allows the inversion of oil flow for the inversion of pump rotation, or alternately with an electric gearmotor, which if mounted under inverter guarantees increased or decreased rotation speed and consequent variation in flow rate.

For better material mixing, the pump is equipped with metal mesh piping for water inlet and a flowmeter that guarantees a constant flow during the phases of mixing and injection.

The pump is also supplied with a diaphragm gauge installed at the pump outlet point that ensures a constant control of the outlet pressure during all work phases. -

Gallery

Lobe pump LB Series

-

Features

Construction and technical characteristics

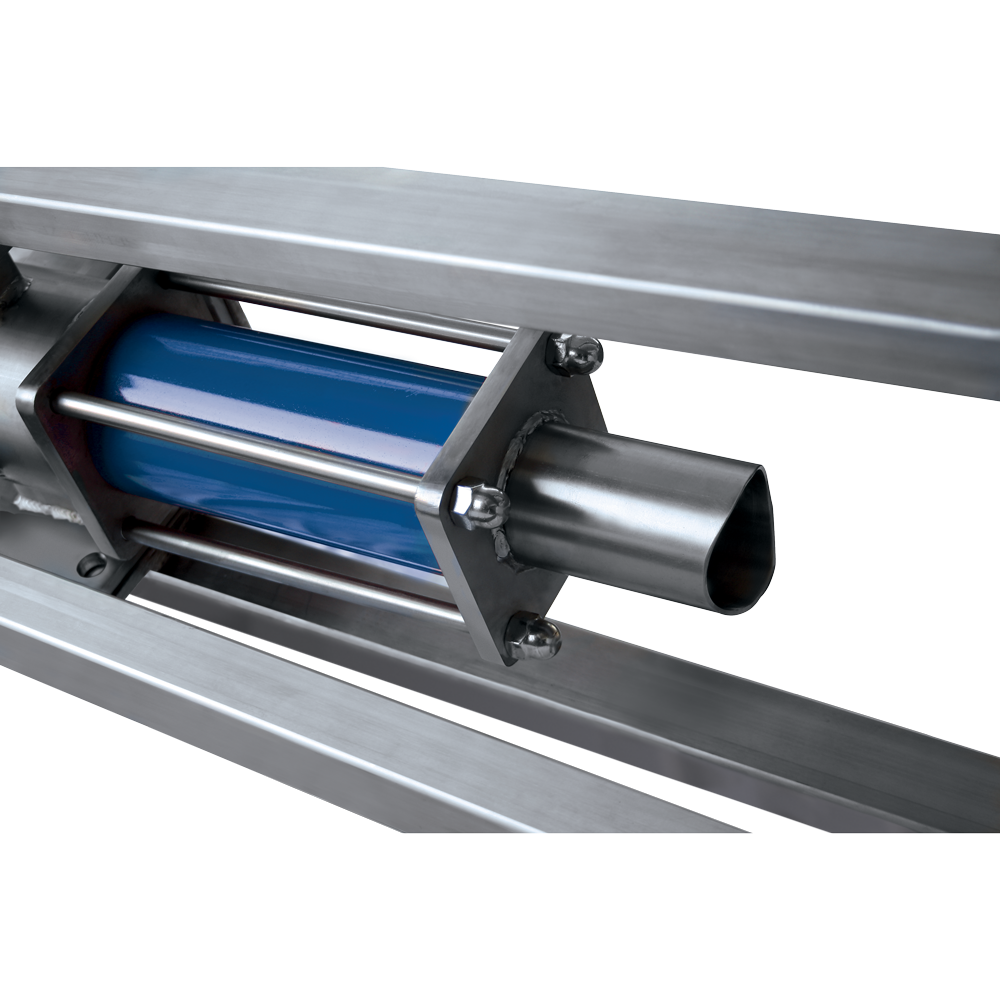

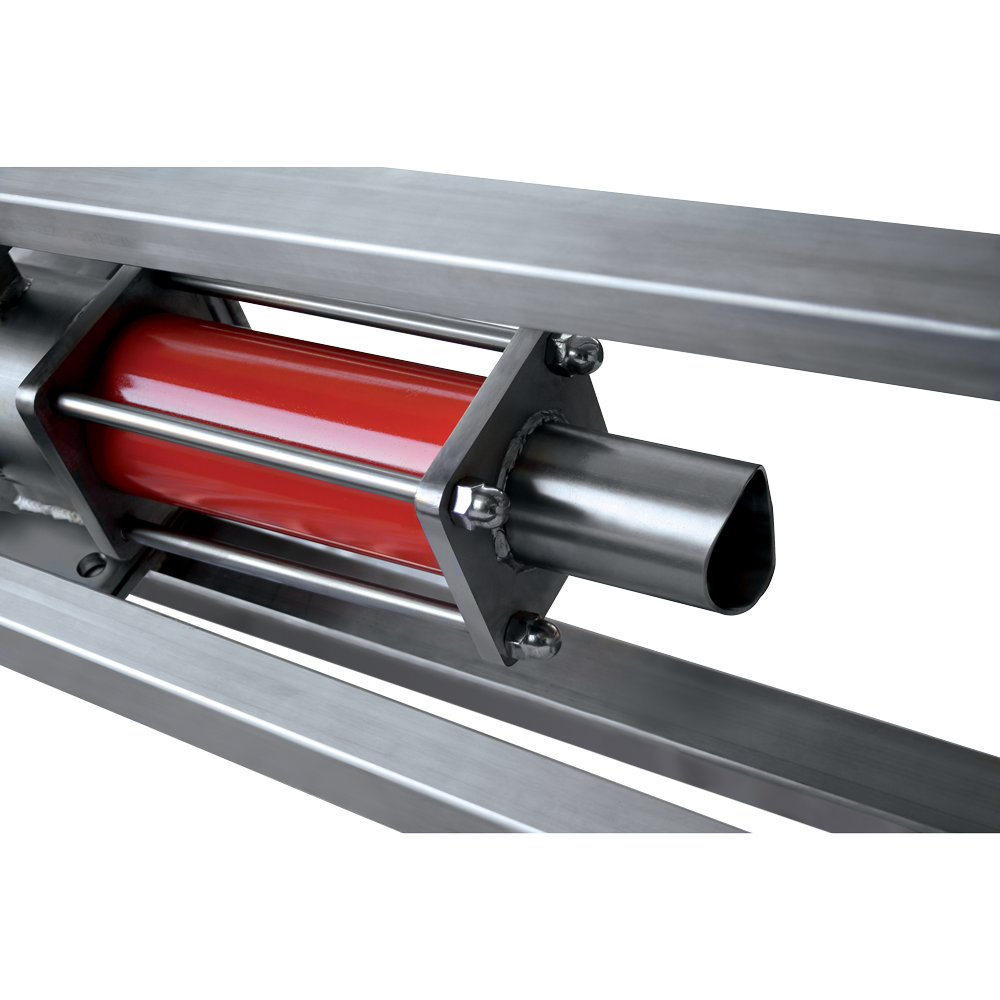

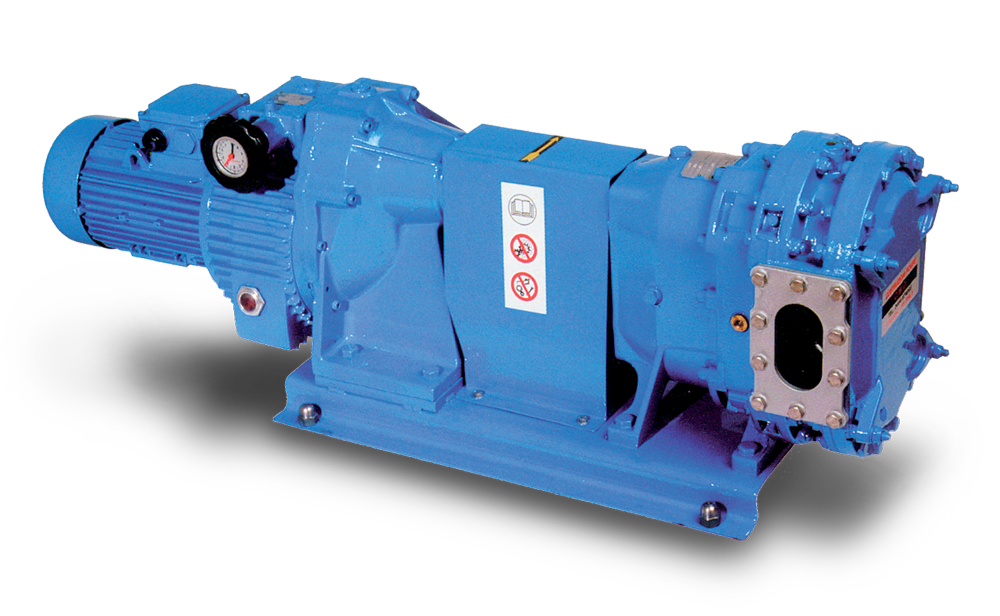

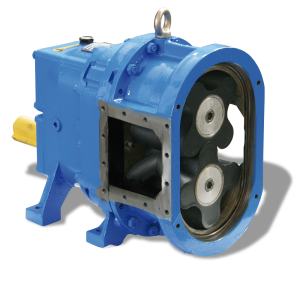

The heart of the machine is made up of two lobe rotors mounted on parallel axes. They rotate in a synchronised manner inversely to each other, inside a proofed chamber. The rotors have three or four lobes, according to the pump size. The combination of the rotor movements creates suction and delivery, and the special helicoidal shape of the lobes guarantees greater fluid movement without any vibrations.

The two rotors can have different coatings, according to the type of material to be pumped. The proofed chamber of the pump is of grey cast iron, and can be thick chromium plated internally if being used with particularly abrasive or aggressive fluids. The mechanical seals are made of tungsten carbide/tungsten carbide.

The important characteristics of this type of pump are:- Compact size, just a little bigger than a rotor pump;

- Easy cleaning and maintenance. The rotors can be replaced without having to dismantle the piping;

- Double rotation: the suction connection can be positioned on the right or on the left.

Field of use

The CMO lobe pump can be used in various fields:

- Agriculture: for expurging stable effluent, diluted excrement, etc.;

- Marble saw mills: for eliminating marble sludge;

- Tanneries: for expurging water containing tanning deposits, etc.;

- Purifying plants: for treating digested primary sludge;

- Building: cement bentonite, polystyrene, lime putty, etc.;

- Drainage: for effluent or regenerating exhausted oils.

-

Gallery

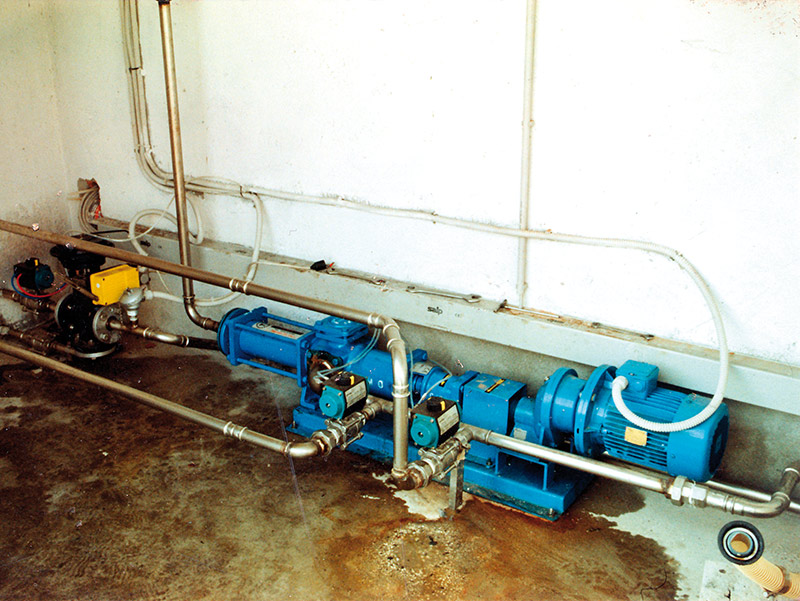

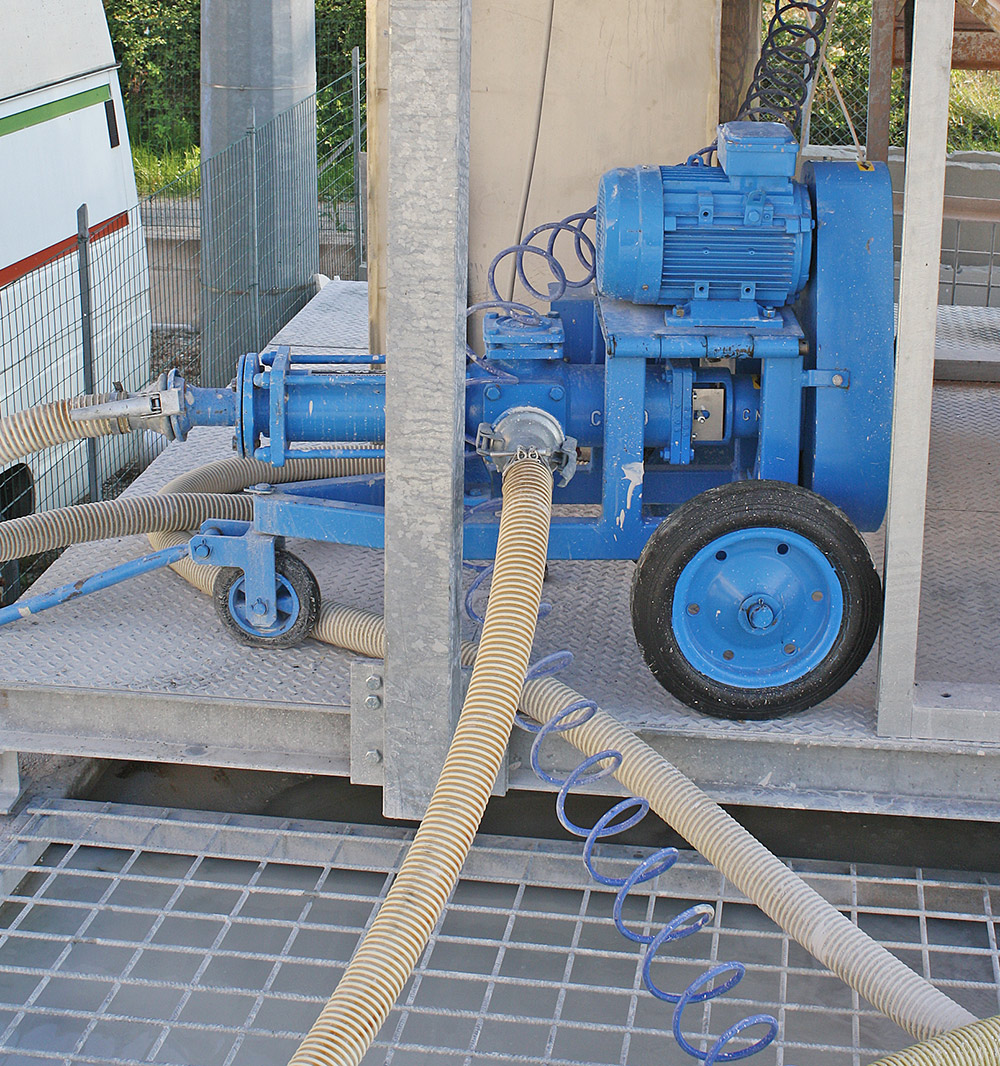

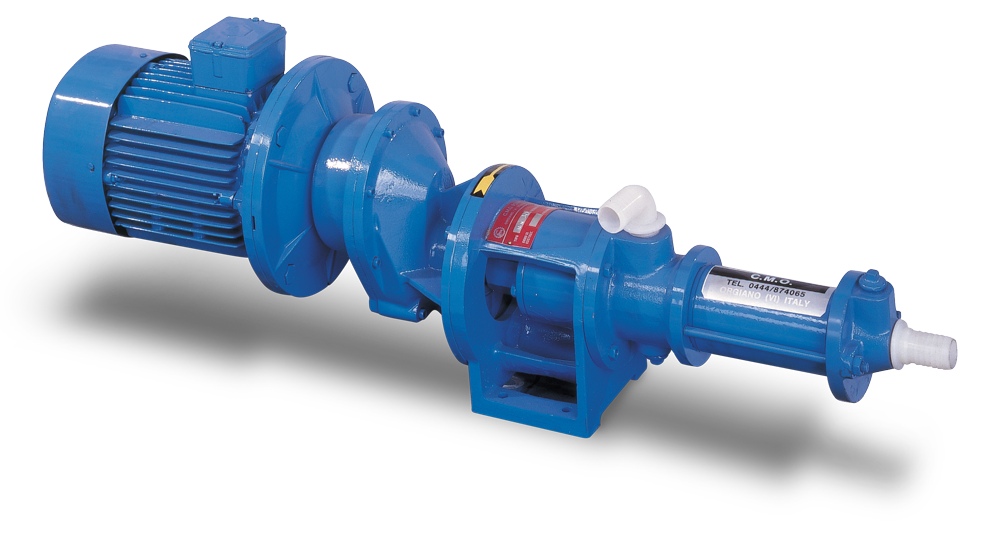

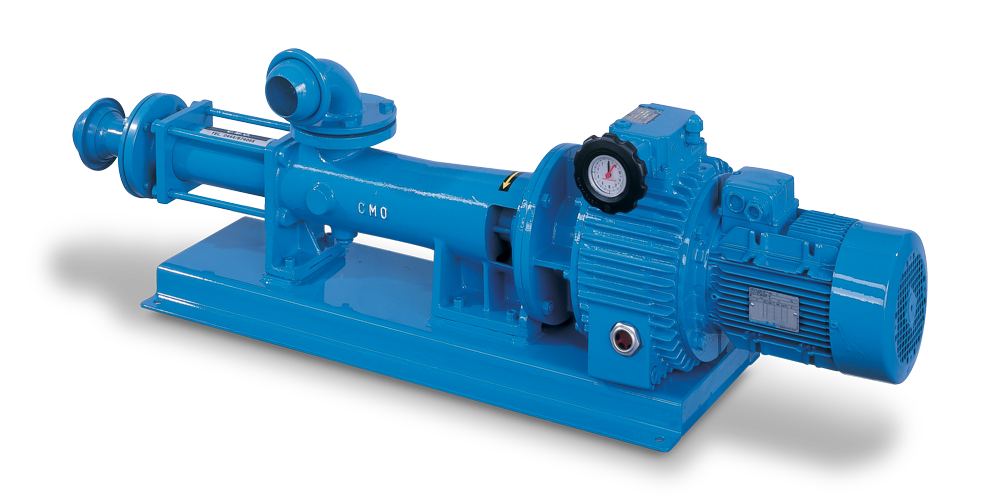

PS | PST Series

-

Features

The CMO pumps with worm feed screw belong to the rotating positive-displacement pump category. With simple construction, the pumps are intended above all for pumping dense and/or viscous fluids.Construction and technical characteristics

The capacity varies depending on the rotor step. The PS series covers a capacity range from 50 to 4000 l/min. The pressure varies with the length of the stator from 0 to 30 bar.

The parts in contact with the liquid are constructed in various materials, depending on the fluid to be pumped. The rotating parts are normally in casehardening or chromium-plated steel or in stainless steel 304 or 316. The stators are constructed in natural or synthetic rubber in different mixes (Viton, Silicon, Perbunan, etc.). Specific materials can be used on request.Field of use

The applications for this type of pump are virtually infinite, due its special construction, the materials used, the technical measures adopted and the singular working mechanism guarantee maximum performance whether pumping brackish water, stall waste, unicellular cement, marble sludge, lime putty, synthetic resins, foundry sludge, etc. When pumping fluids with density and/or abrasion characteristics different to those of water, it is recommended never to reach the pressure limit and capacity values expressed in the table.

For correct function of the pump, it is recommended to check that air is not being suctioned and that the supply of fluid to be pumped is constant to avoid the pump turning dry.

The values featured in the table refer to tests performed with fluids with characteristics similar to those of water.

-

Gallery

-

Technical data

PS SERIES TYPE CAPACITY l/min. HEAD bar POWER HP PS 40 50/7 50 7 3 PS 40 140/7 140 7 3 PS 40 140/20 140 20 4 PS 45 120/7 120 7 4 PS 47 190/7 190 7 4 PS 50 120/10 120 10 4 PS 50 120/30 120 30 7,5 PS 55 200/10 200 10 5,5 PS 55 200/26 200 26 7,5 PS 57 450/7 450 7 5,5 PS 60 370/10 370 10 7,5 PS 60 370/14 370 14 7,5 PS 60 370/20 370 20 10 PS 60 370/26 370 26 10 PS 67 680/7 680 7 12,5 PS 80 520/14 520 14 10 PS 80 520/30 520 30 15 PS 87 960/7 960 7 15 PS 120 870/12 870 12 15 PS 120 870/26 870 25 25 PS 127 1300/7 1300 7 15 PS 200 1230/14 1230 14 20 PS 200 1230/26 1230 26 30 PS 207 2100/7 2700 7 20 PS 300 1400/14 1400 14 30 PS 307 4000/7 4000 7 60 PS 350 2000/14 2000 14 30 PS 400 2800/10 2800 10 30 PS 500 3500/10 3500 10 60 PS SERIES - Twin screw geometry TYPE CAPACITY l/min. HEAD bar POWER HP PS 33 160/7 130 7 4 PS 43 300/10 260 10 5,5 PS 53 410/10 330 10 5,5 PS 63 750/10 470 10 10 PS 83 800/14 600 14 12,5 PS 123 830/12 750 12 15 PS 303 1600/14 1500 14 30 The technical characteristics of the PS and PST series are the same.

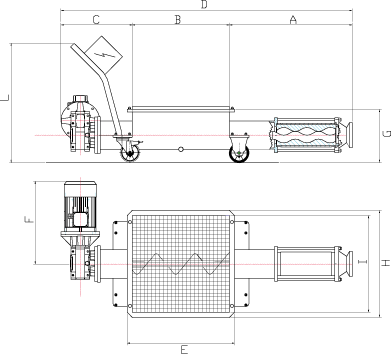

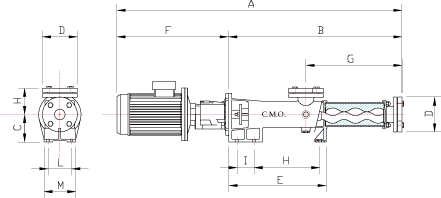

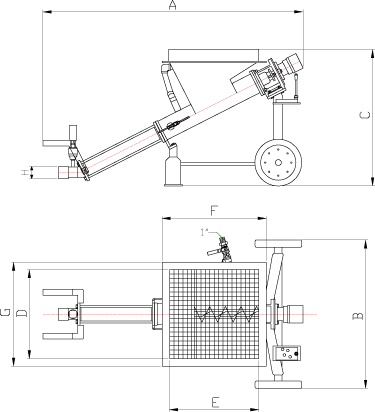

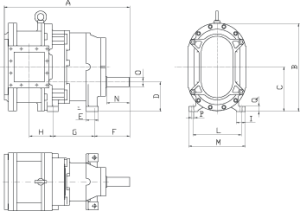

PS SERIES TYPE A B C D E F G H I L M N O P Q R PS 40 50/7 965 540 60 10 120 470 120 15 30 430 160 270 430 32 65 150 PS 40 140/7 920 540 60 10 120 470 120 15 30 390 160 270 390 32 65 150 PS 40 140/20 1130 540 60 10 120 470 120 15 30 590 160 270 590 32 65 150 PS 45 120/7 930 540 60 10 120 470 120 15 30 400 160 270 400 32 65 150 PS 47 190/7 1130 540 60 10 120 470 120 15 30 590 160 270 590 32 65 150 PS 50 120/10 950 540 60 10 120 470 120 15 30 430 160 270 430 32 65 150 PS 50 120/30 1240 540 60 10 120 470 120 15 30 700 160 270 700 32 65 150 PS 55 200/10 960 540 60 10 120 470 120 15 30 440 160 270 440 32 65 150 PS 55 200/26 1260 540 60 10 120 470 120 15 30 725 160 270 725 32 65 150 PS 57 450/7 1200 540 60 10 120 470 120 15 30 680 160 270 680 32 65 150 PS 60 370/10 1300 740 65 10 175 660 140 18 40 620 200 270 550 32 75 140 PS 60 370/14 1410 740 65 10 175 660 140 18 40 720 200 280 660 38 75 140 PS 60 370/20 1540 740 65 10 175 660 140 18 40 850 200 280 800 38 75 140 PS 60 370/26 1650 740 65 10 175 660 140 18 40 960 200 280 900 38 75 140 PS 67 680/7 1600 740 65 10 175 660 140 18 40 920 200 280 860 38 75 140 PS 80 520/14 1410 740 65 10 175 660 140 18 40 720 200 280 660 38 75 140 PS 80 520/30 1850 740 65 10 175 660 140 18 40 1160 200 280 1100 38 75 140 PS 87 960/7 1720 740 65 10 175 660 140 18 40 1030 200 280 970 38 75 140 PS 120 870/12 1480 800 70 10 180 720 140 18 40 940 200 300 660 38 75 140 PS 120 870/26 1920 800 70 10 180 720 140 18 40 1370 200 300 1090 38 75 140 PS 127 1300/7 1870 800 70 10 180 720 140 18 40 1320 200 300 1040 38 75 140 PS 200 1230/14 1560 800 70 10 180 720 140 18 40 1010 200 300 730 38 75 140 PS 200 1230/26 2060 800 70 10 180 720 140 18 40 1510 200 300 1230 38 75 140 PS 207 2100/7 2020 800 70 10 180 720 140 18 40 1450 200 300 1180 38 75 140 PS 300 1400/14 1600 860 70 12 180 720 150 18 50 890 240 390 830 42 78 160 PS 307 4000/7 2800 1315 84 14 195 1190 270 22 65 1880 330 500 - 70 100 245 PS 350 2000/14 1650 860 70 12 180 720 150 18 50 940 240 390 880 42 78 160 PS 400 2800/10 2020 860 70 12 180 720 150 18 50 1380 240 390 1320 42 78 160 PS 500 3500/10 2350 1315 84 14 195 1190 270 22 65 1430 330 500 - 70 100 245 PS SERIES - Twin screw geometry TYPE A B C D E F G H I L M N O P Q R PS 33 160/7 935 540 60 10 120 470 120 15 30 410 160 270 410 32 150 220 PS 43 300/10 990 540 60 10 120 470 120 15 30 470 160 270 470 32 150 220 PS 53 410/10 1000 540 60 10 120 470 120 15 30 480 160 270 480 32 150 220 PS 63 750/10 1345 740 60 10 175 660 140 18 40 665 200 280 595 38 140 260 PS 83 800/14 1410 740 65 10 175 660 140 18 40 720 200 280 660 38 75 140 PS 123 830/12 1480 800 70 10 180 720 140 18 40 940 200 300 660 38 140 260 PS 303 1600/14 1675 860 70 12 180 780 150 18 50 965 240 300 905 42 160 300 The above measurements are indicative only and can be varied at the manufacturer's discretion.

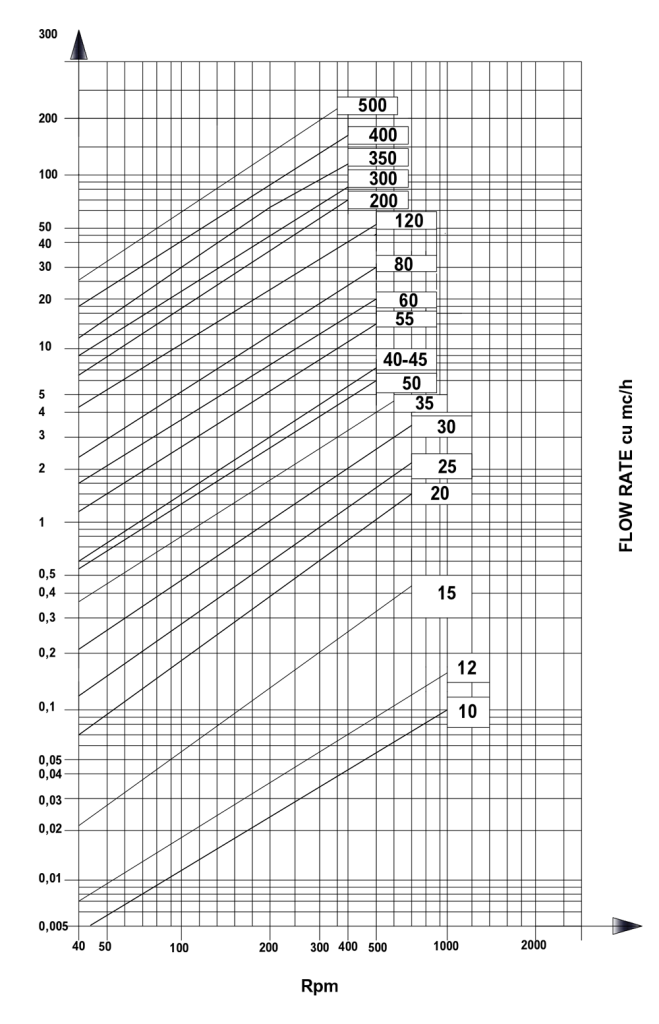

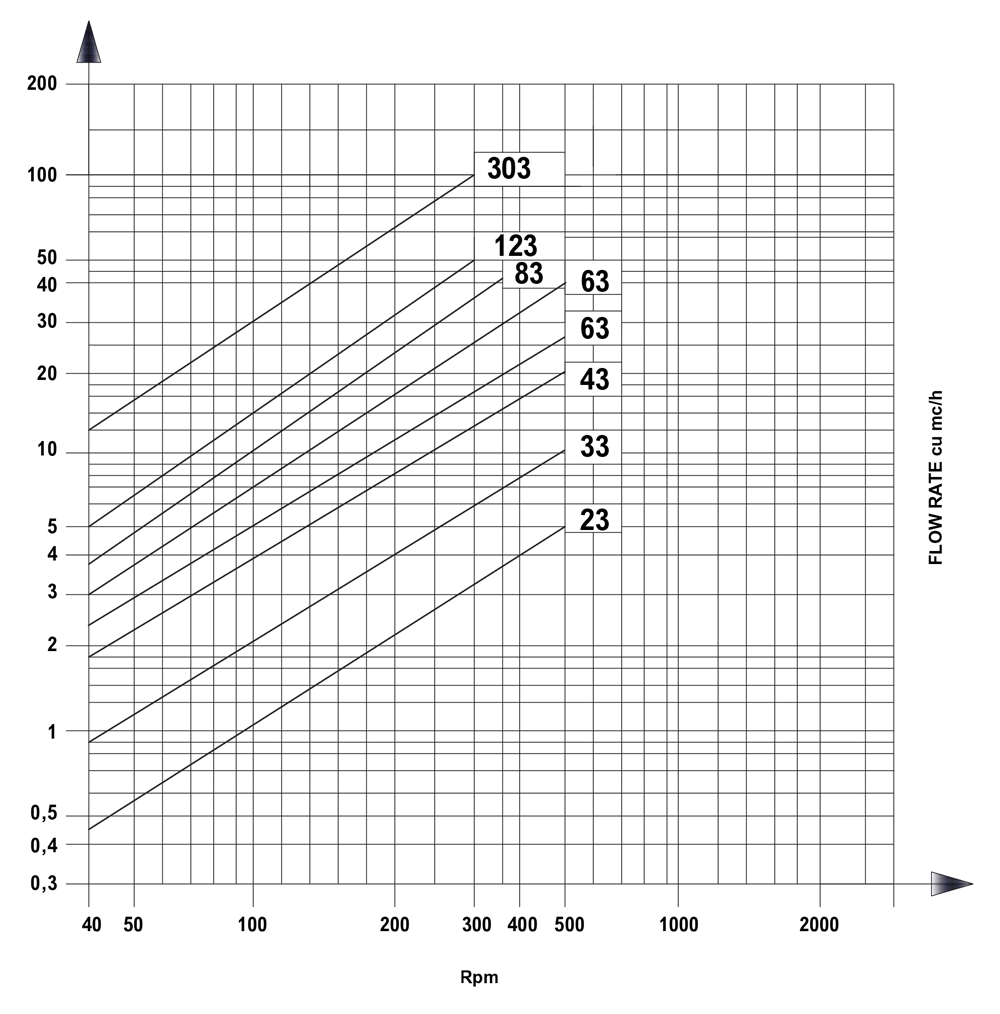

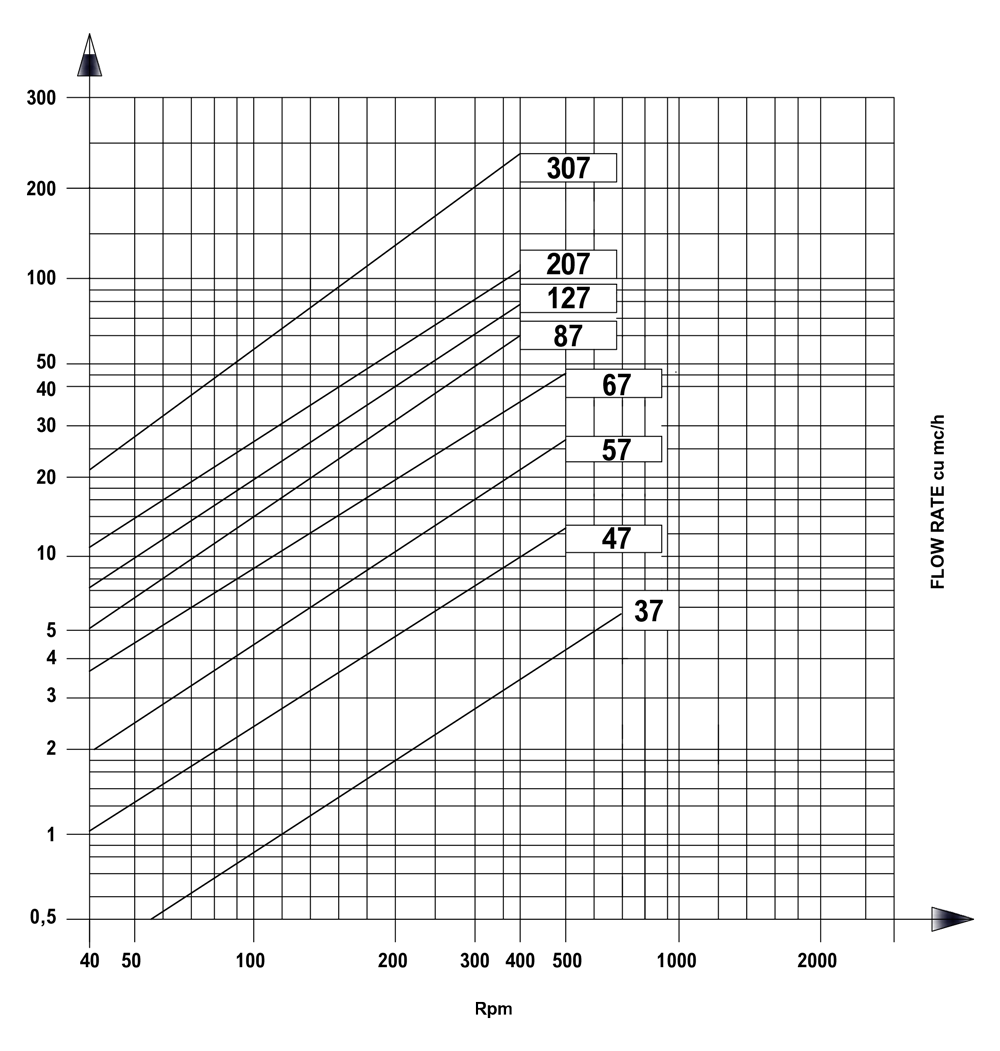

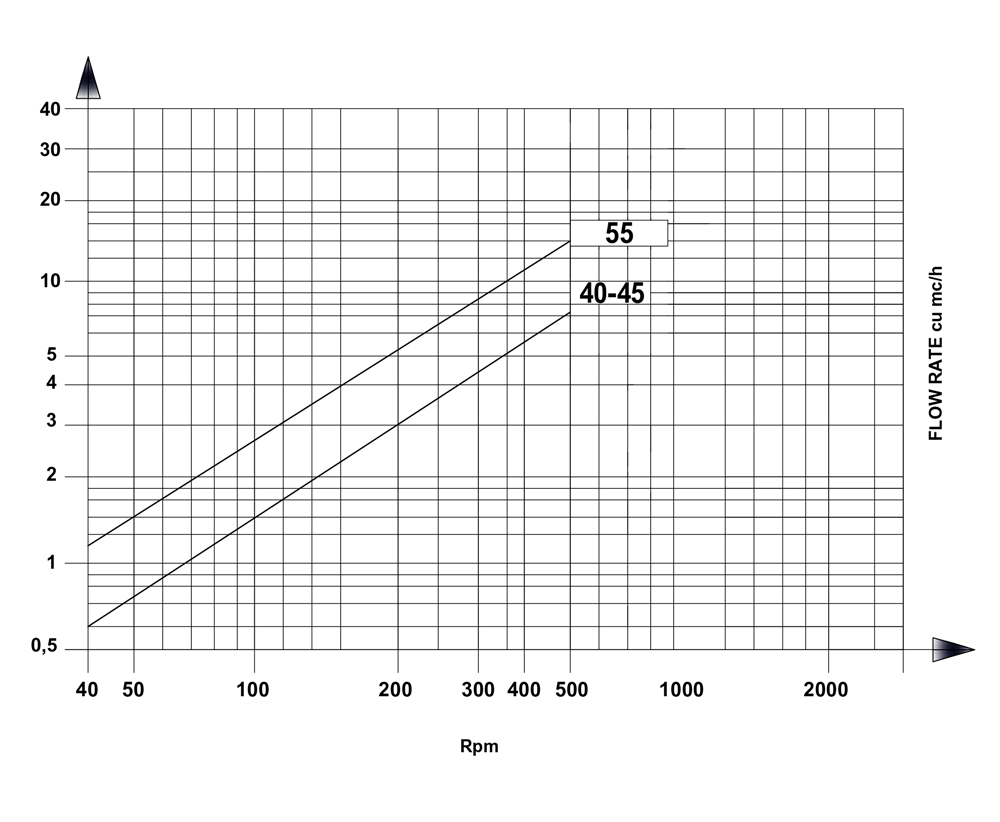

Flow Rate Curves

Standard geometry

HIGHLY ABRASIVE LIQUID SLIGHTLY ABRASIVE LIQUID

Twin screw geometry

HIGHLY ABRASIVE LIQUID SLIGHTLY ABRASIVE LIQUID

Long pitch geometry

HIGHLY ABRASIVE LIQUID SLIGHTLY ABRASIVE LIQUID

Technical data

| PV SERIES | |||

|---|---|---|---|

| TYPE | FLOW RATE l/min. | HEAD bar | POWER HP |

| PV 10 2/5 | 1,2 | 5 | 0,75 |

| PV 12 3/5 | 2,5 | 5 | 0,75 |

| PV 15 10/7 | 10 | 7 | 1 |

| PV 15 10/14 | 10 | 14 | 2 |

| PV 20 20/7 | 20 | 7 | 2 |

| PV 20 20/14 | 20 | 14 | 2 |

| PV 25 30/7 | 20 | 7 | 2 |

| PV 30 60/7 | 30 | 7 | 2 |

| PV 30 60/14 | 60 | 7 | 2 |

| PV 35 90/7 | 90 | 7 | 2 |

| PV 35 90/14 | 90 | 14 | 3 |

| PV 37 100/7 | 100 | 5 | 2 |

| PV 40 50/7 | 50 | 7 | 3 |

| PV 40 140/7 | 140 | 7 | 3 |

| PV 40 140/20 | 140 | 20 | 4 |

| PV 45 120/7 | 120 | 7 | 4 |

| PV 47/190/7 | 190 | 7 | 4 |

| PV 50 120/10 | 120 | 10 | 4 |

| PV 55 200/10 | 200 | 10 | 5,5 |

| PV 57 450/7 | 450 | 7 | 5,5 |

| PV 60 370/10 | 370 | 10 | 7,5 |

| PV 60 370/14 | 370 | 14 | 7,5 |

| PV 67 680/7 | 680 | 7 | 12,5 |

| PV 80 520/14 | 520 | 10 | 10 |

| PV 87 960/7 | 960 | 7 | 15 |

| PV 120 870/12 | 870 | 10 | 15 |

| PV 127 1300/7 | 1300 | 7 | 15 |

| PV 200 1230/14 | 1230 | 10 | 15 |

| PV 207 2100/7 | 2700 | 7 | 20 |

| The flow rates indicated above regard the maximum rpm at 1 bar. The pump’s overall dimensions and connections must be assessed when requesting an estimate. |

|||